Addressing Limitations In Automated Lyophilized Vial Inspection Technology

Table of Contents

Challenges in Detecting Subvisible Particles

Current Automated Lyophilized Vial Inspection Technology struggles with reliably detecting subvisible particles, which can compromise product sterility and efficacy. These particles, smaller than those visible to the naked eye, represent a significant quality control challenge.

Sensitivity Limitations

Several factors contribute to the difficulty of detecting subvisible particles:

- Diffraction limitations of optical systems: The physics of light diffraction limits the resolution of optical systems, hindering the detection of particles smaller than a certain size. Improving this requires advancements in optical technology, potentially incorporating techniques like dark-field microscopy or advanced light scattering methods.

- Variations in vial clarity and fill levels: Differences in glass clarity and the level of lyophilized product within the vial can significantly impact the accuracy of particle detection. Light scattering and refraction are affected by these variations, leading to missed particles or false positives.

- Stricter regulatory requirements: The ongoing tightening of regulatory requirements demands higher sensitivity and resolution in particle detection, pushing the boundaries of current technology. Meeting these demands necessitates continuous innovation in inspection technology.

False Positive Rates

High false positive rates are a significant concern, leading to increased waste, reduced throughput, and ultimately, higher production costs. These false positives arise from various sources:

- Variations in vial geometry and surface imperfections: Minor imperfections in the vial's surface, such as scratches or irregularities in the glass, can be misinterpreted as particles by the inspection system. Advanced algorithms are needed to distinguish between true particles and these artifacts.

- Advanced algorithms and image processing: Sophisticated algorithms and image processing techniques are crucial for minimizing false positives. Machine learning and artificial intelligence are increasingly important in distinguishing between genuine defects and spurious signals.

- Sophisticated quality control measures: Implementing robust quality control measures throughout the inspection process, including regular calibration and validation of the inspection system, is crucial to ensure the reliability of the results.

Addressing Vial Filling Level Variations

Variations in fill height are another significant challenge affecting the accuracy and reliability of Automated Lyophilized Vial Inspection Technology. Inconsistent fill heights can compromise product stability and efficacy.

Inconsistent Fill Heights

Several factors contribute to inconsistent fill heights:

- Current system limitations: Existing automated systems may not always consistently detect small deviations in fill height, leading to inconsistencies in product quality. More precise and sensitive measurement techniques are needed.

- Improved sensor technologies: The development of improved sensor technologies is vital for more precise fill height measurement. This might involve using advanced optical sensors or other non-contact measurement methods.

- Stricter quality control protocols: Implementing stricter quality control protocols during the vial filling process, including regular calibration and maintenance of the filling equipment, can minimize variations in fill height.

Impact on Inspection Accuracy

Inconsistent fill heights significantly impact the accuracy of various inspection parameters:

- Advanced algorithms for compensation: Advanced algorithms that can compensate for fill height variations during particle detection and other inspections are needed. These algorithms should be able to adjust the inspection parameters based on the measured fill height.

- Machine learning for improvement: Machine learning techniques can enhance the accuracy of fill level detection and compensation, allowing the system to learn and adapt to variations in fill height.

- Adaptive automated systems: The development of automated systems capable of adapting to varying fill heights is crucial for ensuring consistent and accurate inspection results.

Overcoming Limitations in Vial Appearance Inspection

Automated systems must effectively identify defects such as cracks, scratches, or discoloration to maintain product quality. Current technology faces challenges in reliably detecting these subtle defects.

Detecting Defects in Vial Appearance

Limitations in current image processing techniques hinder accurate defect detection:

- Advanced image analysis algorithms: Development of advanced image analysis algorithms capable of detecting subtle defects is crucial. These algorithms should be capable of identifying variations in color, texture, and shape that indicate defects.

- Integration of various imaging modalities: Integrating various imaging modalities, such as visible light, near-infrared (NIR), or ultraviolet (UV) imaging, can enhance defect detection capabilities by providing complementary information.

- Improved image quality and resolution: Improved image quality and resolution are critical for reliable defect detection. Optimizing lighting conditions, camera settings, and image processing techniques are essential.

Improving Image Acquisition and Processing

Optimizing image acquisition and processing is critical for reliable defect detection:

- Optimized lighting and camera settings: Optimizing lighting conditions and camera settings, such as using specialized lighting techniques or high-resolution cameras, is critical for improved image acquisition.

- Noise and artifact filtering algorithms: Developing algorithms that can effectively filter out noise and artifacts from the images is necessary for accurate defect detection.

- Advanced machine learning for pattern recognition: Employing advanced machine learning techniques for improved pattern recognition and defect classification is crucial for distinguishing between genuine defects and artifacts.

Conclusion

Automated Lyophilized Vial Inspection Technology is crucial for maintaining the quality and safety of pharmaceutical products. While significant advancements have been made, limitations in detecting subvisible particles, handling fill level variations, and inspecting vial appearance remain. Addressing these challenges requires further development in sensor technology, image processing algorithms, and machine learning techniques. By investing in research and development to overcome these limitations, the pharmaceutical industry can ensure the continued reliability and efficacy of Automated Lyophilized Vial Inspection Technology, ultimately improving patient safety and product quality. The future of efficient and reliable pharmaceutical manufacturing hinges on the continuous improvement of this crucial technology. Investing in advanced Automated Lyophilized Vial Inspection Technology is an investment in patient safety and product efficacy.

Featured Posts

-

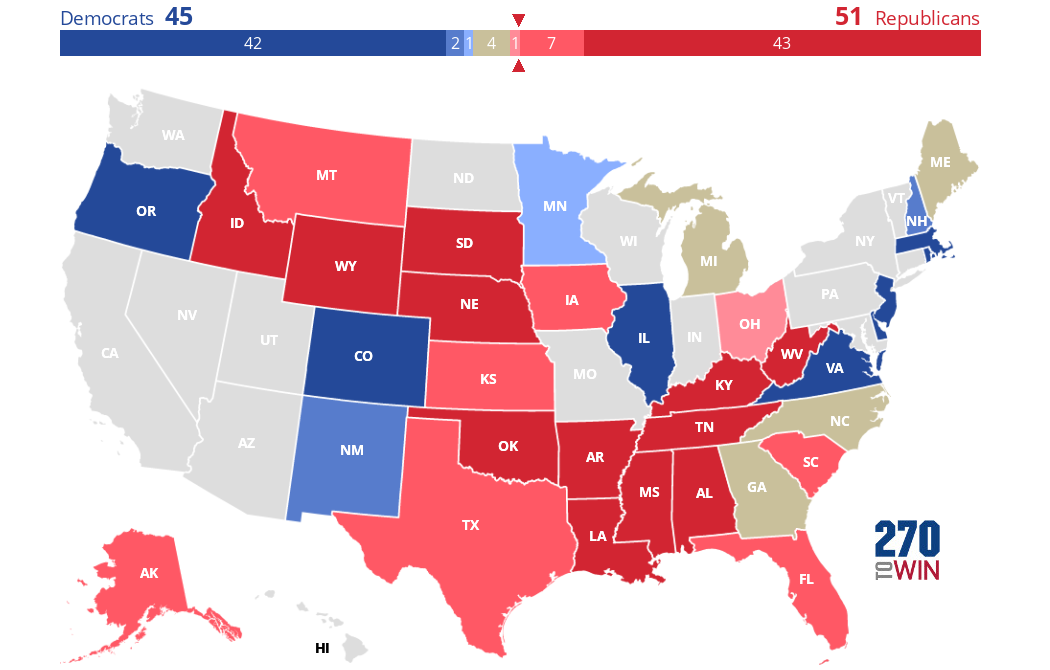

Susan Collins 2026 Senate Re Election Bid Democrats Eyeing A Challenge

May 12, 2025

Susan Collins 2026 Senate Re Election Bid Democrats Eyeing A Challenge

May 12, 2025 -

Bce Inc Dividend Cut Reasons And Investor Implications

May 12, 2025

Bce Inc Dividend Cut Reasons And Investor Implications

May 12, 2025 -

Manon Fiorots Rise A Contenders Journey

May 12, 2025

Manon Fiorots Rise A Contenders Journey

May 12, 2025 -

Ufc 315 Muhammad Vs Della Maddalena Full Main Card Results And Fight Analysis

May 12, 2025

Ufc 315 Muhammad Vs Della Maddalena Full Main Card Results And Fight Analysis

May 12, 2025 -

Karlyn Pickens Historic 78 2 Mph Pitch Redefining Ncaa Softball

May 12, 2025

Karlyn Pickens Historic 78 2 Mph Pitch Redefining Ncaa Softball

May 12, 2025