Decarbonizing Steel Production: Eramet's EraLow Manganese Alloy

Table of Contents

Understanding the Environmental Impact of Traditional Steel Production

Traditional steelmaking processes, primarily reliant on blast furnaces, are incredibly energy-intensive and release vast amounts of CO2 into the atmosphere. This contributes significantly to global warming and climate change, making the search for sustainable steel production paramount. The environmental challenges associated with current methods are multifaceted and severe:

- High energy consumption leading to significant CO2 emissions: Blast furnaces require enormous amounts of energy, typically derived from fossil fuels, leading to a substantial carbon footprint. Reducing carbon emissions steel production is key.

- Reliance on fossil fuels for energy: The dependence on coal and coke for blast furnace operations directly contributes to greenhouse gas emissions. This presents a major obstacle to creating sustainable steel.

- Generation of significant waste products: Traditional steelmaking generates considerable waste, including slag and dust, which require careful management and disposal.

- Contribution to global warming and climate change: The cumulative effect of these emissions contributes significantly to global warming and the accelerating climate crisis. The steel industry's impact on CO2 steel production is undeniable.

Eramet's eraLow Manganese Alloy: A Technological Breakthrough

Eramet's eraLow manganese alloy represents a technological leap forward in sustainable steelmaking. This low-carbon manganese alloy offers a compelling alternative to traditional methods, significantly reducing the environmental impact of steel production. Its innovative composition and production process contribute to a reduced carbon footprint:

- Reduced reliance on coke in steelmaking: eraLow allows for a significant reduction in coke consumption, a major source of CO2 emissions in traditional blast furnaces.

- Improved energy efficiency in the steel production process: The eraLow process leads to improved energy efficiency, further reducing the overall energy consumption and associated emissions.

- Lower CO2 emissions compared to traditional methods: Independent studies demonstrate significantly lower CO2 emissions per ton of steel produced using eraLow compared to conventional methods. This makes eraLow a critical component of low-carbon steel production.

- Potential for significant reductions in greenhouse gas emissions: Widespread adoption of eraLow has the potential to dramatically reduce greenhouse gas emissions from the steel industry, contributing substantially to global climate goals.

- Enhanced material properties compared to traditional manganese alloys: eraLow not only offers environmental benefits but also enhances the mechanical properties of the resulting steel, leading to improved performance in various applications.

The Science Behind eraLow's Carbon Reduction

The secret to eraLow's carbon reduction lies in its unique composition and the resulting optimized chemical reactions during the steelmaking process. Precisely controlled alloying elements interact to reduce the need for high-temperature processes and the associated energy consumption and CO2 emissions. This advanced understanding of manganese alloy properties allows for a more efficient and environmentally friendly steel production method, setting a new standard for sustainable steelmaking technology.

Benefits of Using eraLow Manganese Alloy in Steel Production

Adopting eraLow offers numerous advantages, extending beyond environmental benefits to encompass economic considerations as well. The advantages are compelling for businesses seeking both sustainability and profitability:

- Reduced carbon footprint, contributing to environmental sustainability goals: EraLow allows steel producers to significantly reduce their environmental impact, aligning with global sustainability initiatives and regulatory requirements. This is a critical aspect of producing green steel.

- Potential for cost savings due to improved energy efficiency: Reduced energy consumption translates to direct cost savings for steel producers, enhancing the economic viability of adopting eraLow.

- Enhanced material properties leading to improved steel quality: The enhanced properties of steel produced with eraLow can lead to improved performance and durability, potentially commanding premium prices in the market.

- Compliance with increasingly stringent environmental regulations: EraLow helps steel producers comply with increasingly stringent environmental regulations, avoiding potential penalties and reputational damage.

- Contribution to a circular economy: The process contributes to the principles of a circular economy by reducing waste and promoting resource efficiency.

The Future of Steel Production with eraLow

Eramet's vision for eraLow extends beyond a single product; it represents a paradigm shift in steel production. The future of steel hinges on sustainable solutions, and eraLow is poised to play a pivotal role:

- Potential for large-scale adoption across the steel industry: Eramet is actively collaborating with steel producers globally to facilitate the widespread adoption of eraLow.

- Collaboration with steel producers to facilitate widespread implementation: Eramet is committed to supporting steelmakers in transitioning to eraLow, providing technical expertise and assistance.

- Continuous research and development to further improve the technology: Eramet continues to invest in R&D to further optimize eraLow and explore additional improvements in sustainable steelmaking.

- Contribution to achieving global climate goals: The widespread adoption of eraLow can significantly contribute to achieving global climate goals and mitigating the impact of climate change. This is a significant step toward a sustainable steel future.

Conclusion

Eramet's eraLow manganese alloy represents a significant advancement in the quest for decarbonizing steel production. Its unique properties offer a viable pathway to significantly reduce carbon emissions associated with steelmaking, creating a more sustainable and environmentally responsible steel industry. This low-carbon steel solution addresses the urgent need for green steel alternatives.

Call to Action: Learn more about how Eramet's eraLow manganese alloy can help your company achieve its sustainability goals and contribute to a greener future. Contact us today to discuss integrating this innovative, low-carbon steel solution into your steel production processes. Embrace the eraLow revolution in sustainable steel!

Featured Posts

-

Swiatek To Fall From No 2 Ranking Following Rome Loss To Collins

May 14, 2025

Swiatek To Fall From No 2 Ranking Following Rome Loss To Collins

May 14, 2025 -

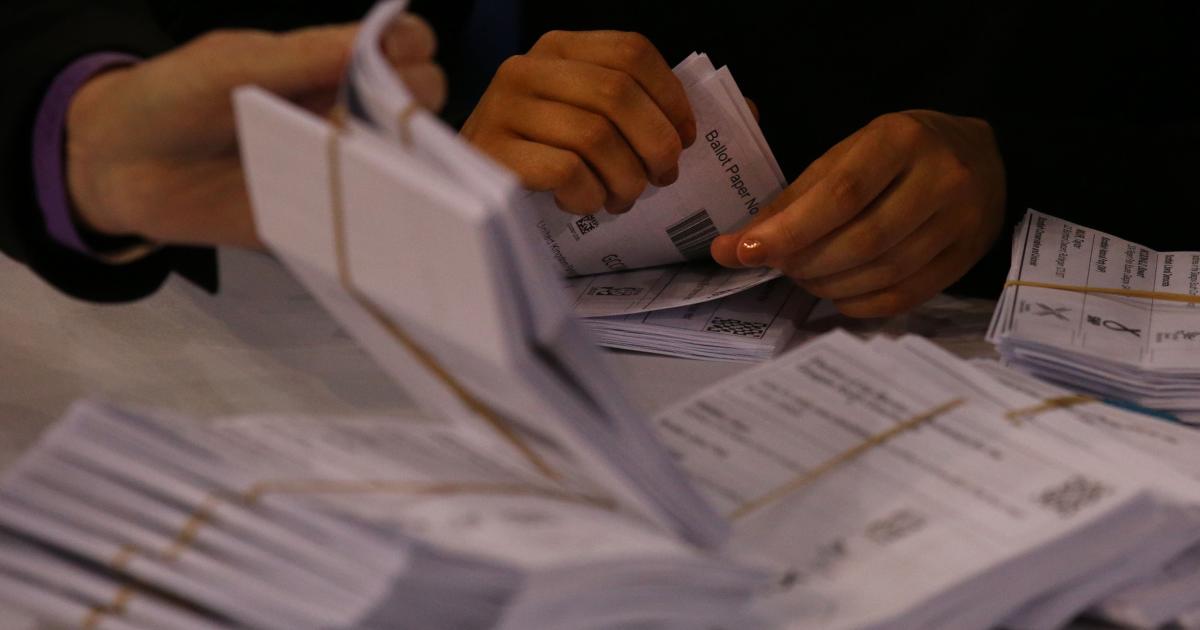

Portugals Prime Minister Faces Uncertainty Could May Bring An Election

May 14, 2025

Portugals Prime Minister Faces Uncertainty Could May Bring An Election

May 14, 2025 -

Your Guide To Dynamax Sobble In Pokemon Go Max Mondays Battles

May 14, 2025

Your Guide To Dynamax Sobble In Pokemon Go Max Mondays Battles

May 14, 2025 -

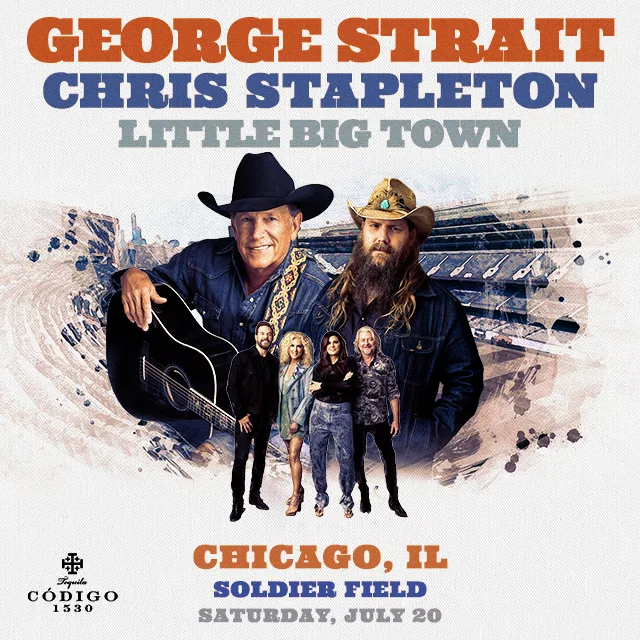

See The Dates George Strait And Chris Stapletons Joint 2025 Stadium Tour

May 14, 2025

See The Dates George Strait And Chris Stapletons Joint 2025 Stadium Tour

May 14, 2025 -

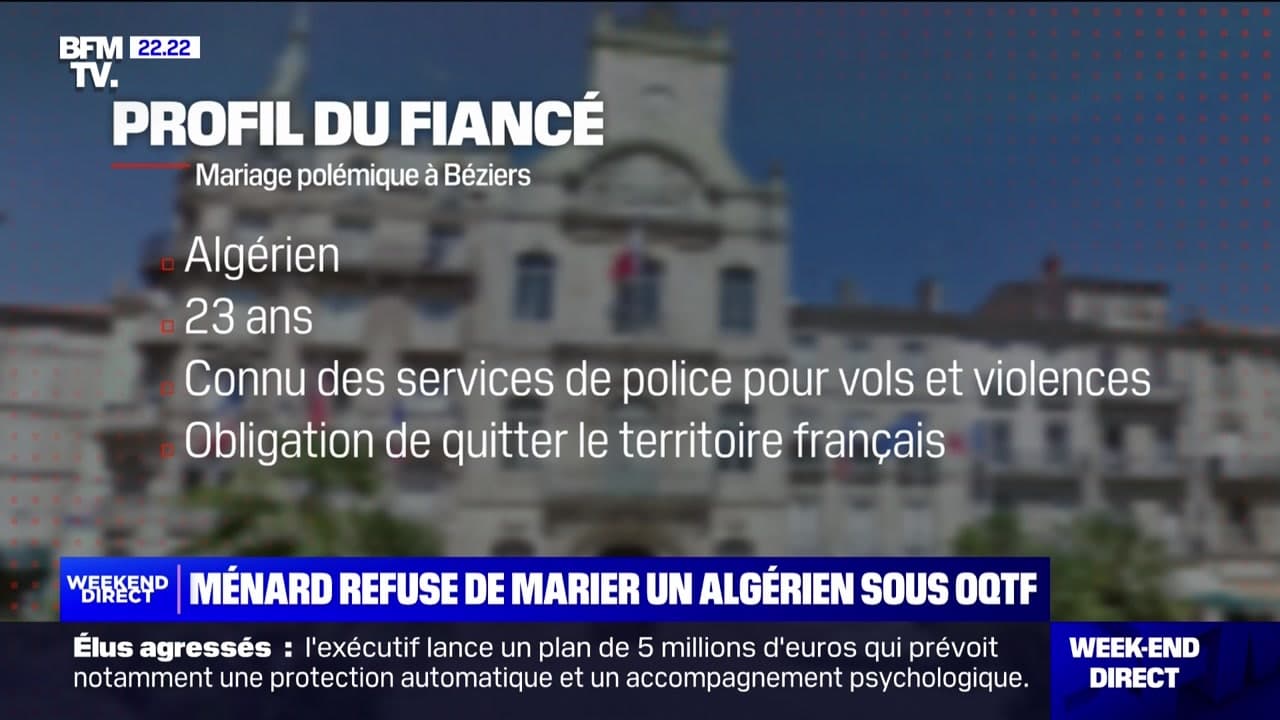

Expulsion Sous Oqtf Le Drame De Deux Collegiens Et Leur Mere Pendant Les Vacances Scolaires

May 14, 2025

Expulsion Sous Oqtf Le Drame De Deux Collegiens Et Leur Mere Pendant Les Vacances Scolaires

May 14, 2025