Enhanced Automated Visual Inspection Of Lyophilized Vials: Addressing Key Challenges

Table of Contents

Improving Accuracy and Reducing Human Error in Lyophilized Vial Inspection

Limitations of Manual Inspection

Manual visual inspection of lyophilized vials is inherently prone to limitations. Human inspectors are susceptible to fatigue, leading to inconsistencies and potential overlooking of defects. This subjectivity introduces variability in defect classification and inspection rates.

- Subjectivity in defect classification: Different inspectors may classify the same defect differently, leading to inconsistencies in quality control.

- Inconsistent inspection rates: Fatigue and variations in attention can lead to inconsistent inspection speeds and thoroughness.

- High false-positive/false-negative rates: Human error can lead to both incorrectly rejecting good vials (false positives) and accepting defective vials (false negatives).

- Increased risk of human error: Long inspection periods increase the likelihood of mistakes, potentially compromising product safety.

Advantages of Automated Systems

Automated visual inspection systems offer significant advantages over manual methods. These systems provide objective defect detection and minimize human error, resulting in improved accuracy and consistency.

- Enhanced sensitivity to subtle defects: Automated systems can detect subtle defects often missed by the human eye, improving the overall quality control.

- Consistent inspection parameters: Automated systems maintain consistent inspection parameters throughout the process, ensuring uniformity and reliability.

- Objective defect classification: Automated systems classify defects based on pre-defined parameters, eliminating subjective interpretations.

- Improved throughput and efficiency: Automated systems significantly increase the speed of inspection, leading to higher throughput and reduced processing times.

Advanced Imaging Technologies for Lyophilized Vials

Automated visual inspection systems utilize various advanced imaging technologies to detect defects in lyophilized vials.

- High-resolution cameras: Provide detailed images for detecting cracks, particulate matter, and discoloration. Limitations may include challenges with differentiating subtle variations in cake appearance.

- Spectral imaging: Analyzes the spectral signature of the lyophilized product to identify variations in composition or degradation, detecting defects invisible to standard cameras. This method can be more expensive and complex to implement.

- 3D imaging: Creates a three-dimensional representation of the vial and its contents, allowing for the detection of defects not visible in 2D imaging, such as internal cracks or variations in cake structure. This technology is typically more complex and expensive.

Increasing Throughput and Efficiency in Lyophilized Vial Production

Bottlenecks in Manual Inspection

Manual inspection is a significant bottleneck in lyophilized vial production. The slow inspection rates necessitate large inspection teams, significantly increasing labor costs and potentially delaying product release.

- Slow inspection rates: Manual inspection is significantly slower than automated systems, limiting overall production capacity.

- Dependence on large inspection teams: Meeting production demands requires a large workforce dedicated solely to inspection.

- Increased labor costs: High labor costs associated with large inspection teams negatively impact profitability.

- Potential delays in product release: Inspection bottlenecks can cause delays in product release, impacting time-to-market.

Automation's Role in Streamlining the Process

Automated visual inspection systems significantly increase throughput, streamlining the production process and reducing lead times.

- High-speed inspection capabilities: Automated systems can inspect vials at significantly higher speeds than manual inspection, boosting overall production capacity.

- Reduced labor requirements: Automation reduces the need for a large inspection team, saving labor costs and resources.

- Increased production capacity: Higher throughput allows for increased production capacity without expanding the workforce.

- Potential for 24/7 operation: Automated systems can operate continuously, further increasing production output.

Integration with Existing Production Lines

Integrating automated visual inspection systems into existing lyophilization production lines is feasible and highly beneficial. Seamless data transfer and workflow optimization are key advantages.

- Compatibility with various vial sizes and formats: Modern systems are designed to accommodate various vial sizes and formats.

- Integration with existing data management systems: Data from automated systems can be integrated with existing data management systems for enhanced traceability and reporting.

- Minimal disruption to existing workflows: Well-planned integration minimizes disruption to existing production workflows.

- Cost-effectiveness of integration: While the initial investment may be significant, the long-term cost savings often outweigh the initial expense.

Ensuring Data Integrity and Regulatory Compliance in Automated Lyophilized Vial Inspection

Data Management and Traceability

Data integrity and traceability are crucial for regulatory compliance (e.g., 21 CFR Part 11). Automated systems provide secure data storage and comprehensive audit trails.

- Secure data logging and archiving: Automated systems ensure secure storage and archiving of inspection data.

- Audit trails: Complete audit trails track all system actions and changes, providing a verifiable record of the inspection process.

- Electronic signatures: Electronic signatures enhance the security and integrity of the inspection process.

- Compliance with relevant regulations: Automated systems are designed to meet the requirements of relevant regulatory guidelines.

Validation and Qualification of Automated Systems

Validation and qualification are essential to ensure the accuracy and reliability of automated inspection systems.

- IQ/OQ/PQ protocols: Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols ensure the system is installed, operates, and performs as intended.

- Performance verification testing: Regular performance verification testing validates the system's ongoing accuracy and reliability.

- Ongoing system monitoring: Continuous monitoring of system performance ensures early detection of potential problems.

- Maintenance and calibration schedules: Regular maintenance and calibration schedules ensure the continued accuracy and precision of the system.

Reporting and Analytics

Automated reporting and data analytics capabilities provide valuable insights for process improvement.

- Real-time defect detection reports: Real-time reports provide immediate feedback on defect rates and trends.

- Trend analysis: Trend analysis helps identify potential issues and improve process control.

- Identification of process improvement opportunities: Data analysis reveals areas for process optimization.

- Proactive defect prevention strategies: By identifying root causes of defects, proactive prevention strategies can be implemented.

Conclusion

Enhanced Automated Visual Inspection of Lyophilized Vials offers significant advantages, including improved accuracy, increased efficiency, and enhanced regulatory compliance. By reducing human error, increasing throughput, and improving data integrity, automated systems optimize lyophilized vial production processes, ensuring the highest quality and safety standards. Invest in enhanced automated visual inspection to transform your lyophilized vial inspection process. Improve your lyophilized vial inspection process today and learn more about automated lyophilized vial inspection systems by contacting us.

Featured Posts

-

How To Meet Shane Lowry Tips And Strategies

May 12, 2025

How To Meet Shane Lowry Tips And Strategies

May 12, 2025 -

Jose Aldo L Adaptateur Pour Continuer A Avancer

May 12, 2025

Jose Aldo L Adaptateur Pour Continuer A Avancer

May 12, 2025 -

Discover Montego Bay Beaches Culture And Beyond

May 12, 2025

Discover Montego Bay Beaches Culture And Beyond

May 12, 2025 -

3 Must See Mma Fights 5 10 And 25 Minute Thrillers Mma Torch

May 12, 2025

3 Must See Mma Fights 5 10 And 25 Minute Thrillers Mma Torch

May 12, 2025 -

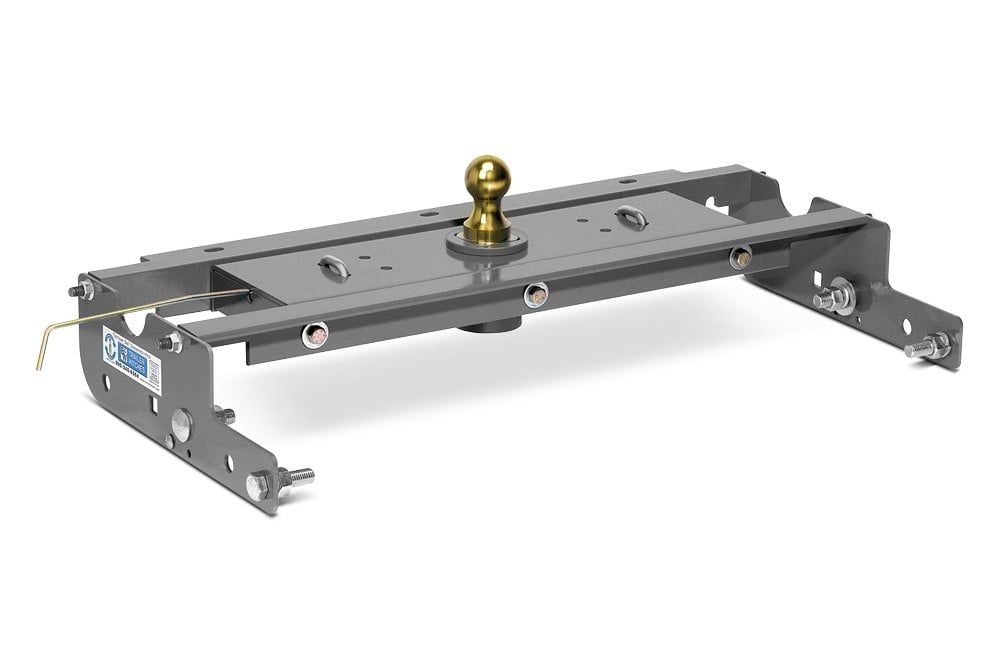

B And W Trailer Hitches All Star Bass Fishing Tournament 100 K Up For Grabs At Smith Mountain Lake Next Week

May 12, 2025

B And W Trailer Hitches All Star Bass Fishing Tournament 100 K Up For Grabs At Smith Mountain Lake Next Week

May 12, 2025