Ensuring Quality Control: Addressing Challenges In Automated Lyophilized Vial Inspection

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Vials

Automated systems for inspecting lyophilized vials aim to detect defects quickly and reliably, but several factors complicate this process.

Variability in Lyophilized Cakes

The appearance of the lyophilized cake—the dried drug product within the vial—is highly variable. Inconsistencies significantly impact automated detection.

- Cracks: Fine or large cracks in the cake can indicate problems with the freeze-drying process.

- Collapse: Complete or partial collapse of the cake affects drug stability and reconstitution.

- Uneven Surfaces: Irregular surfaces make consistent automated inspection difficult.

Differentiating between acceptable variations in cake appearance and actual defects that compromise product quality requires sophisticated algorithms and careful calibration. Lighting conditions significantly affect image processing, and even slight variations can lead to misinterpretations by the automated system.

Contamination Detection Limitations

Identifying particulate matter, foreign bodies (e.g., glass fragments, rubber particles), and other forms of contamination remains a significant challenge.

- Particulate Matter: Microscopic particles can be difficult to detect against the background of the lyophilized cake.

- Foreign Bodies: Larger contaminants are easier to spot but require algorithms capable of identifying various shapes and sizes.

- Microbial Contamination: While not directly visible, the presence of microbial contamination might indirectly lead to observable changes in the lyophilized cake's structure which could be detected.

Current automated systems struggle with detecting subtle contamination, especially when particles are small or similar in color to the lyophilized product. High-resolution imaging and carefully controlled lighting are crucial for improving detection accuracy.

False Positives and False Negatives

Inaccurate classifications by automated systems lead to significant problems: false positives result in wasted product, while false negatives allow defective vials to enter the supply chain.

- False Positives: Shadows, reflections, and even slight variations in the vial's surface can be misinterpreted as defects.

- False Negatives: Subtle cracks, minor collapses, or small contaminants can be missed by the automated system's algorithms.

The balance between sensitivity and specificity in automated lyophilized vial inspection is crucial, as errors directly impact overall product quality, efficiency, and ultimately, patient safety.

Improving Automated Lyophilized Vial Inspection Processes

Addressing the challenges requires a multi-faceted approach focusing on technological advancements, algorithm optimization, and robust quality control procedures.

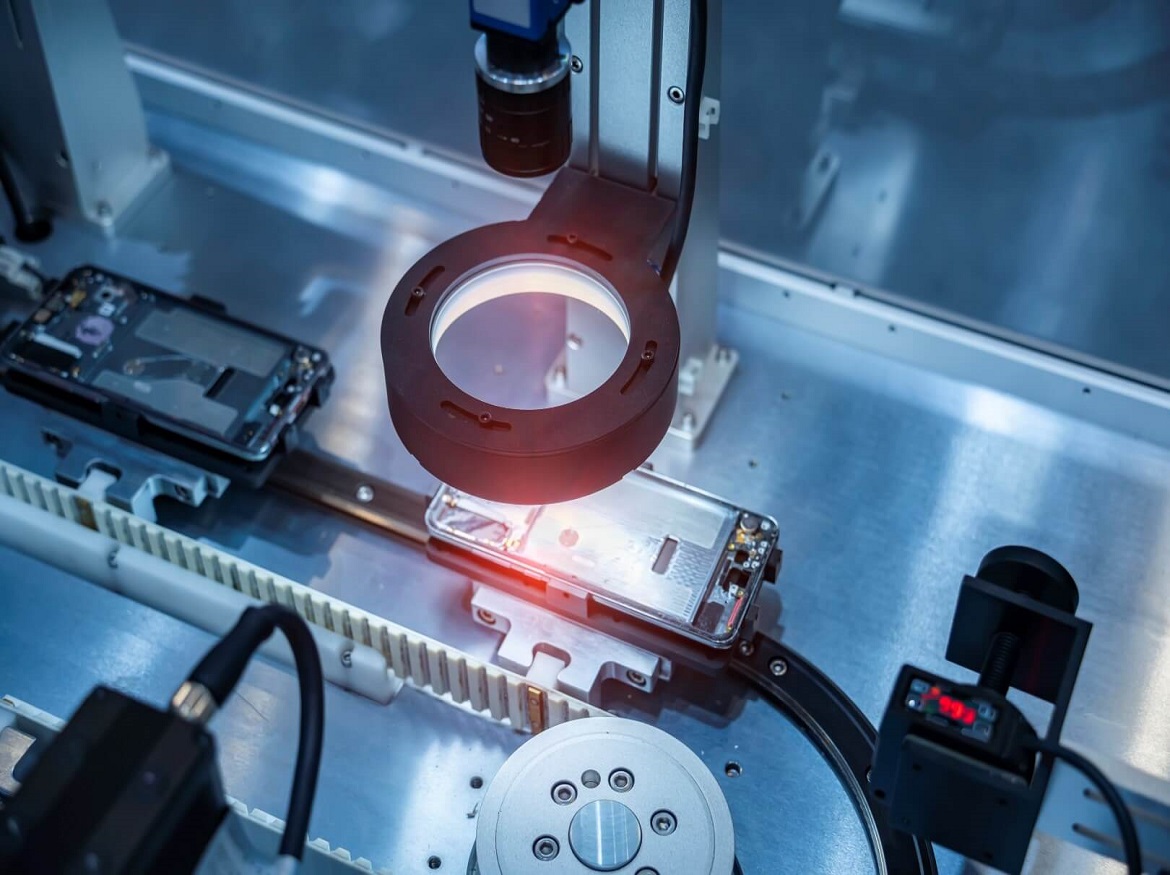

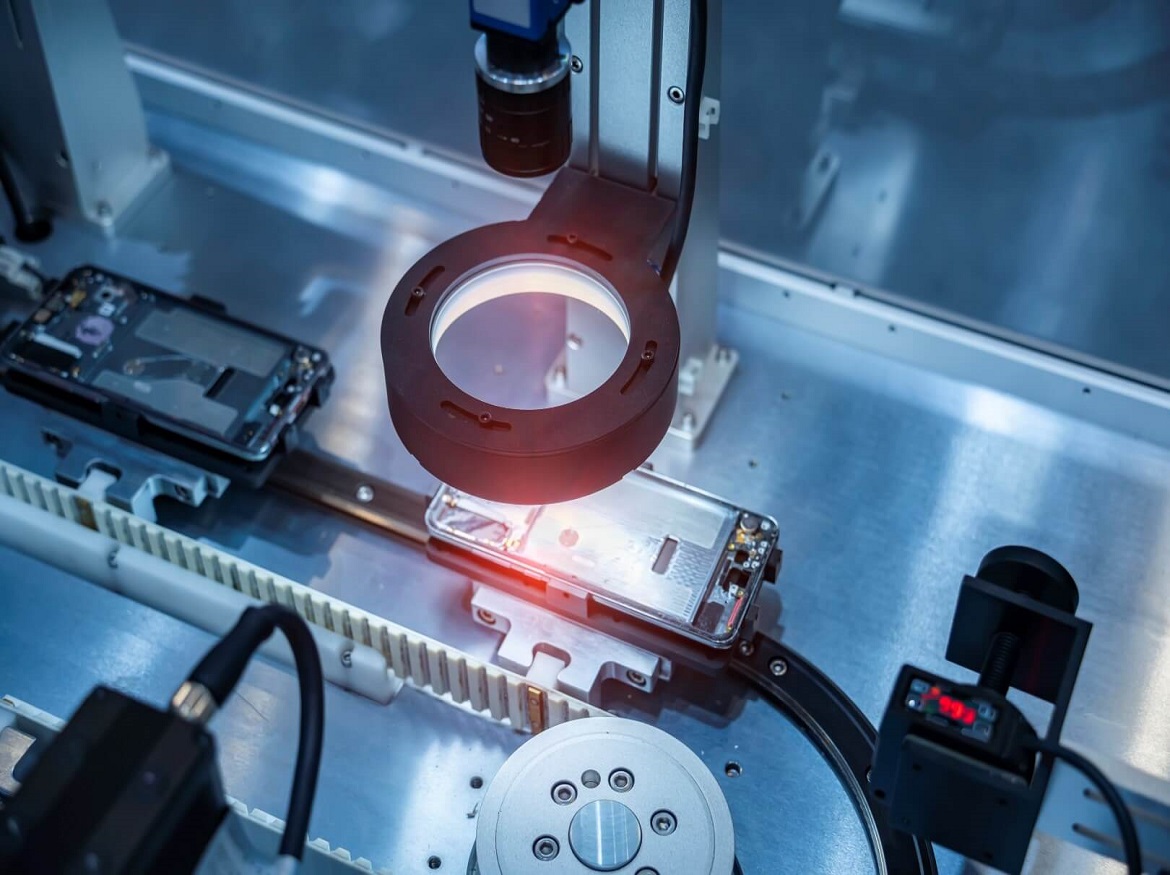

Advanced Imaging Techniques

Implementing advanced imaging technologies can greatly improve defect detection.

- Hyperspectral Imaging: Captures detailed spectral information, enhancing the differentiation between product and contaminants.

- 3D Imaging: Provides a three-dimensional view of the lyophilized cake, allowing for better detection of subtle defects and irregularities.

While these techniques offer significant advantages, they are also more complex and costly to implement than traditional 2D imaging.

Optimized Algorithm Development

Sophisticated machine learning (ML) and artificial intelligence (AI) algorithms are crucial for accurate defect classification.

- Training Datasets: Large, high-quality datasets are essential for training robust and accurate algorithms.

- Algorithm Refinement: Continuous monitoring and refinement are necessary to adapt to changing conditions and improve accuracy.

- Human-in-the-Loop: Integrating human review into the inspection process for validating algorithm performance and providing feedback for ongoing improvement is highly beneficial.

Robust Quality Control Procedures

Comprehensive quality control goes beyond automated inspection, encompassing the entire production process.

- Upstream Process Controls: Minimizing defects at the source is crucial; this includes rigorous control of the freeze-drying process itself.

- System Validation: Rigorous validation of automated inspection systems is essential to ensure they consistently meet performance requirements.

- Data Management: Effective data management systems are necessary for tracking and analyzing inspection results, identifying trends, and guiding continuous improvement efforts.

Future Trends in Automated Lyophilized Vial Inspection

The field of automated lyophilized vial inspection is constantly evolving.

Integration of Data Analytics

Big data and analytics will play an increasingly important role in predicting and preventing defects by identifying patterns and trends in production data.

Increased Automation and Robotics

Fully automated systems with minimal human intervention will become more prevalent, streamlining the inspection process and further enhancing efficiency.

Focus on Digitalization and Traceability

Integrated digital systems will improve record-keeping, track vials throughout the production process, and enhance overall traceability.

Ensuring Quality Control in Automated Lyophilized Vial Inspection

Ensuring the quality of lyophilized vials is vital; overcoming challenges in automated inspection requires a combination of advanced imaging techniques, sophisticated algorithms, and rigorous quality control procedures. Automated Lyophilized Vial Inspection is essential for modern pharmaceutical manufacturing, and by implementing the strategies discussed in this article, manufacturers can significantly improve the accuracy and effectiveness of their inspection processes, leading to higher quality products and enhanced patient safety. Invest in advanced automated lyophilized vial inspection systems to enhance your product quality and efficiency. Contact us today to learn more about upgrading your quality control processes.

Featured Posts

-

Win Tickets To Sold Out Tales From The Track Presented By Relay

May 11, 2025

Win Tickets To Sold Out Tales From The Track Presented By Relay

May 11, 2025 -

Ksiaze Andrzej I Masazystka Szczegoly Kontrowersyjnego Zabiegu

May 11, 2025

Ksiaze Andrzej I Masazystka Szczegoly Kontrowersyjnego Zabiegu

May 11, 2025 -

Mueller Lockas Bort Fran Bayern Intresse Fran Tva Klubbar

May 11, 2025

Mueller Lockas Bort Fran Bayern Intresse Fran Tva Klubbar

May 11, 2025 -

Next Pope Leading Contenders And Their Platforms

May 11, 2025

Next Pope Leading Contenders And Their Platforms

May 11, 2025 -

Shop The Latest 2025 New York Yankees Hats Jerseys And Apparel

May 11, 2025

Shop The Latest 2025 New York Yankees Hats Jerseys And Apparel

May 11, 2025