Eramet's EraLow: A Decarbonization Breakthrough In Manganese Alloys

Table of Contents

The eraLow Process: A Technological Leap in Manganese Alloy Production

Traditional manganese alloy production is a significant contributor to greenhouse gas emissions. The process typically involves high-temperature smelting using significant quantities of fossil fuels, resulting in substantial CO2 output. Furthermore, the energy intensity of traditional methods contributes to a larger carbon footprint.

Eramet's eraLow process represents a paradigm shift. It leverages several key innovations to dramatically reduce its environmental impact. The core differentiators of eraLow lie in its optimized energy efficiency, reduced reliance on fossil fuels, and the integration of sustainable practices throughout the production chain.

-

Improved energy efficiency through optimized smelting techniques: Eramet has implemented advanced smelting techniques that significantly reduce energy consumption per ton of manganese alloy produced. This optimization minimizes the overall energy demand and subsequently decreases CO2 emissions.

-

Reduced reliance on fossil fuels by integrating renewable energy sources: eraLow incorporates renewable energy sources, such as hydroelectricity and solar power, into its production process. This transition from fossil fuels to cleaner energy sources is a critical factor in lowering the carbon footprint.

-

Implementation of carbon capture and storage (CCS) technologies where applicable: Where feasible, Eramet integrates carbon capture and storage technologies to further mitigate CO2 emissions. This cutting-edge technology captures CO2 before it enters the atmosphere and stores it safely underground.

-

Use of alternative raw materials with lower carbon footprints: Eramet is actively exploring and utilizing alternative raw materials with lower embodied carbon, further contributing to the reduction of the overall carbon footprint of the eraLow process. This includes sourcing materials from more sustainable and responsible suppliers.

Environmental Benefits of eraLow: A Significant Reduction in Carbon Footprint

The eraLow process boasts a significantly reduced carbon footprint compared to traditional manganese alloy production methods. Independent audits have confirmed a reduction of up to 40% in CO2 emissions per ton of manganese alloy produced. This translates to a substantial decrease in overall greenhouse gas emissions from steel production, contributing positively to global climate goals.

The eraLow process adheres to stringent environmental standards and certifications, underscoring its commitment to sustainability. Eramet is actively pursuing further certifications and is committed to transparent reporting of its environmental performance.

-

Significant reduction in CO2 emissions per ton of manganese alloy produced: This is the primary environmental benefit, directly addressing the concerns of climate change.

-

Lower energy consumption leading to decreased reliance on fossil fuels: The optimized process reduces the demand for fossil fuels, lowering reliance on non-renewable energy sources.

-

Contribution to achieving global climate goals and sustainability targets: The eraLow process actively supports international efforts to reduce greenhouse gas emissions and meet climate change targets.

Market Impact and Applications of eraLow: Shaping the Future of Sustainable Steel

The market demand for sustainable manganese alloys is rapidly increasing, driven by growing environmental awareness and stricter regulations within the steel industry. eraLow is ideally positioned to capture significant market share due to its superior sustainability profile. Manganese alloys are crucial components in various steel applications, including:

- Stainless steel: Used in countless applications, from kitchenware to industrial equipment.

- High-strength steel: Essential for construction, automotive, and other industries requiring high durability.

By using eraLow, steel manufacturers can produce greener steel products, meeting the growing demand for sustainable materials. This contributes to a circular economy and reduces the environmental impact of the entire steel production chain.

-

Increased demand from environmentally conscious steel manufacturers: Steel producers are increasingly seeking sustainable alternatives, creating high demand for eraLow.

-

Competitive advantage for steel producers using eraLow alloys: The reduced carbon footprint provides a significant competitive edge in the market.

-

Potential for partnerships and collaborations to expand the use of eraLow: Eramet is actively seeking collaborations to accelerate the adoption of its sustainable technology.

The Future of eraLow: Continued Innovation and Expansion

Eramet is committed to the continuous improvement and expansion of the eraLow technology. Ongoing research and development efforts focus on further reducing the carbon footprint and enhancing the efficiency of the production process. This includes exploring new technologies and refining existing processes to maximize sustainability. Eramet is also actively working on scaling up the eraLow process to meet the growing global demand for sustainable manganese alloys. The company envisions expanding its production capacity to meet the needs of a rapidly expanding market.

Conclusion

Eramet's eraLow represents a significant advancement in sustainable manganese alloy production. By dramatically reducing CO2 emissions and improving energy efficiency, eraLow offers a compelling solution for the decarbonization of the steel industry. Its innovative technology, coupled with its positive environmental impact and strong market potential, positions eraLow as a crucial element in the creation of a greener future for steel manufacturing. Learn more about how Eramet's eraLow can help your company achieve its sustainability goals; contact us today to explore the benefits of this revolutionary solution for your manganese alloy needs. Discover the potential of Eramet eraLow and contribute to a more sustainable steel industry.

Featured Posts

-

Fallecimiento De Jose Mujica Reflexiones Sobre Su Presidencia En Uruguay

May 14, 2025

Fallecimiento De Jose Mujica Reflexiones Sobre Su Presidencia En Uruguay

May 14, 2025 -

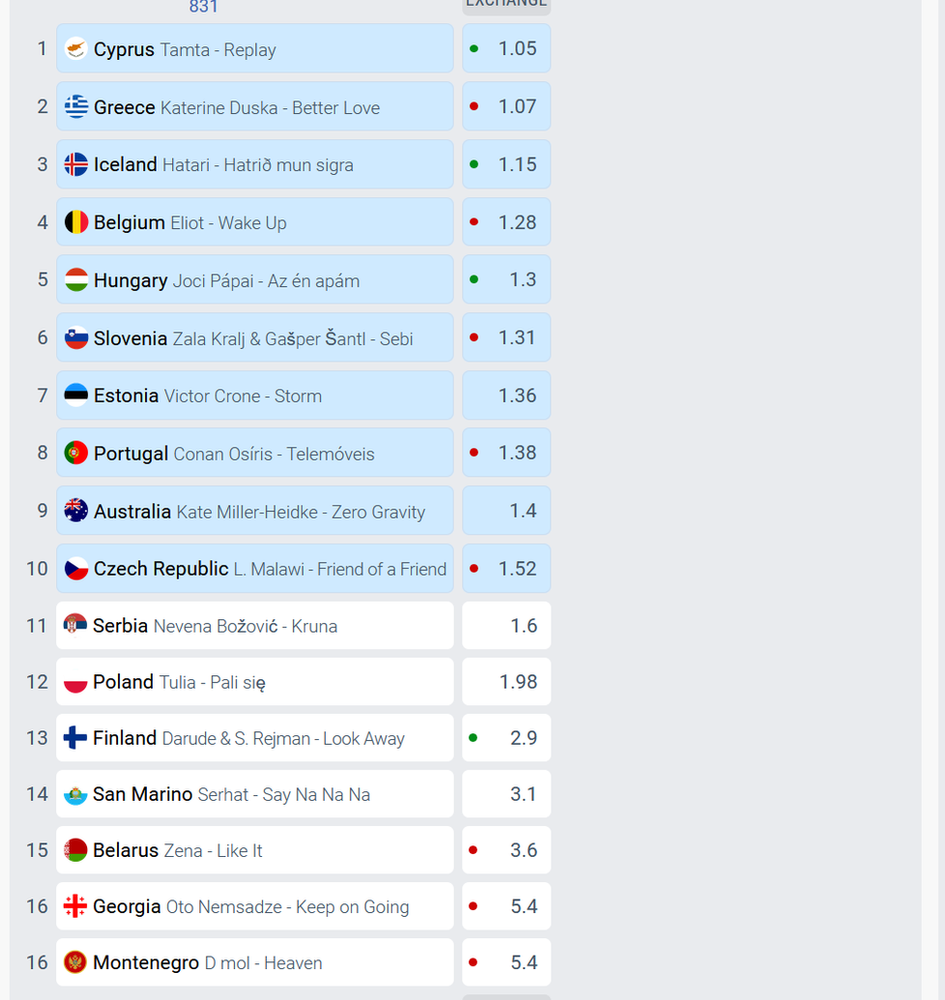

Swedens Eurovision Odds Favor A Victory

May 14, 2025

Swedens Eurovision Odds Favor A Victory

May 14, 2025 -

Finaliza La Etapa De Garcia Pimienta En El Sevilla Caparros Toma El Mando

May 14, 2025

Finaliza La Etapa De Garcia Pimienta En El Sevilla Caparros Toma El Mando

May 14, 2025 -

Jet Blue Airways Delays Haiti Return Amid Civil Unrest

May 14, 2025

Jet Blue Airways Delays Haiti Return Amid Civil Unrest

May 14, 2025 -

Suits La Episode 2 Ted Blacks Unused Superpower And My Frustration

May 14, 2025

Suits La Episode 2 Ted Blacks Unused Superpower And My Frustration

May 14, 2025