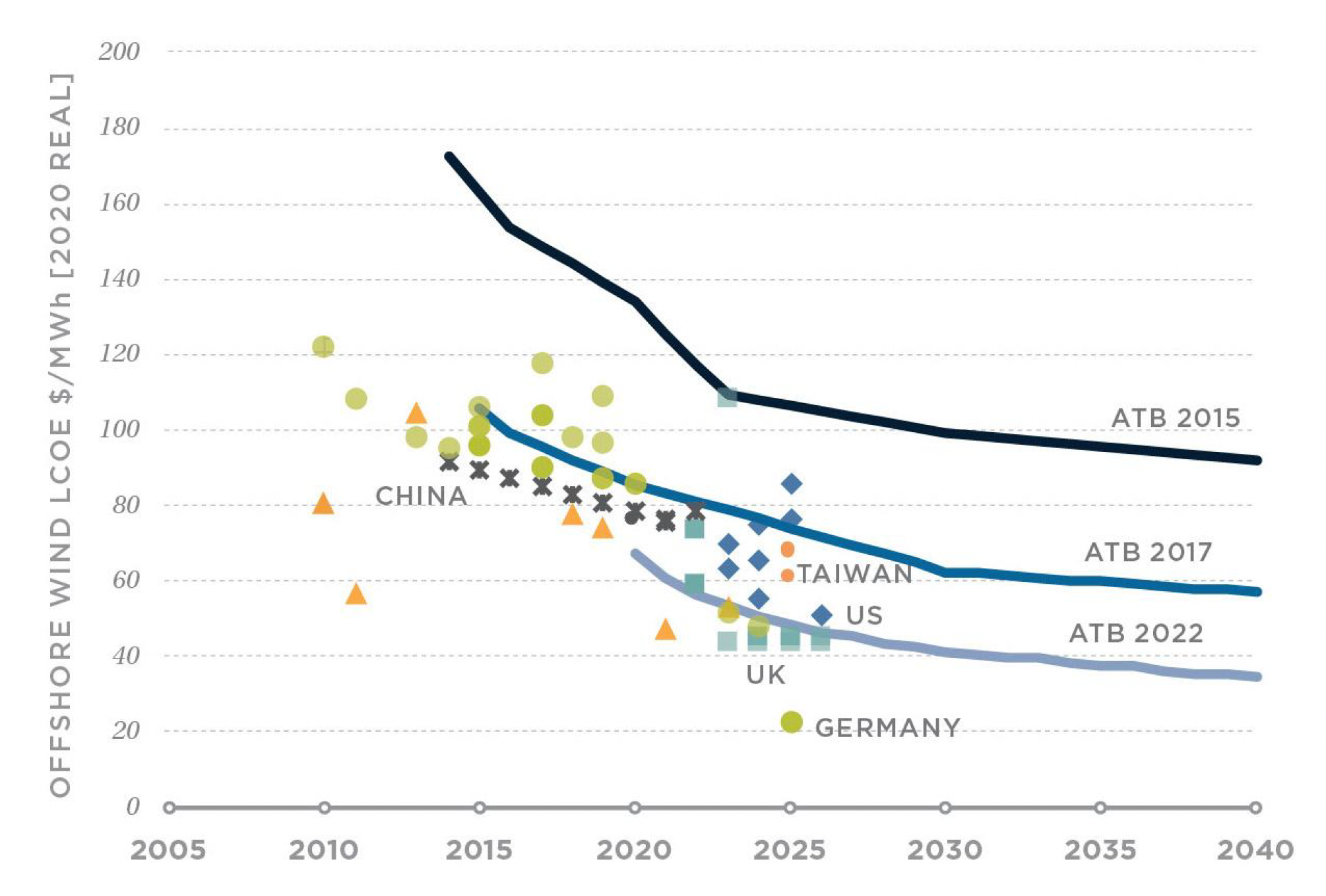

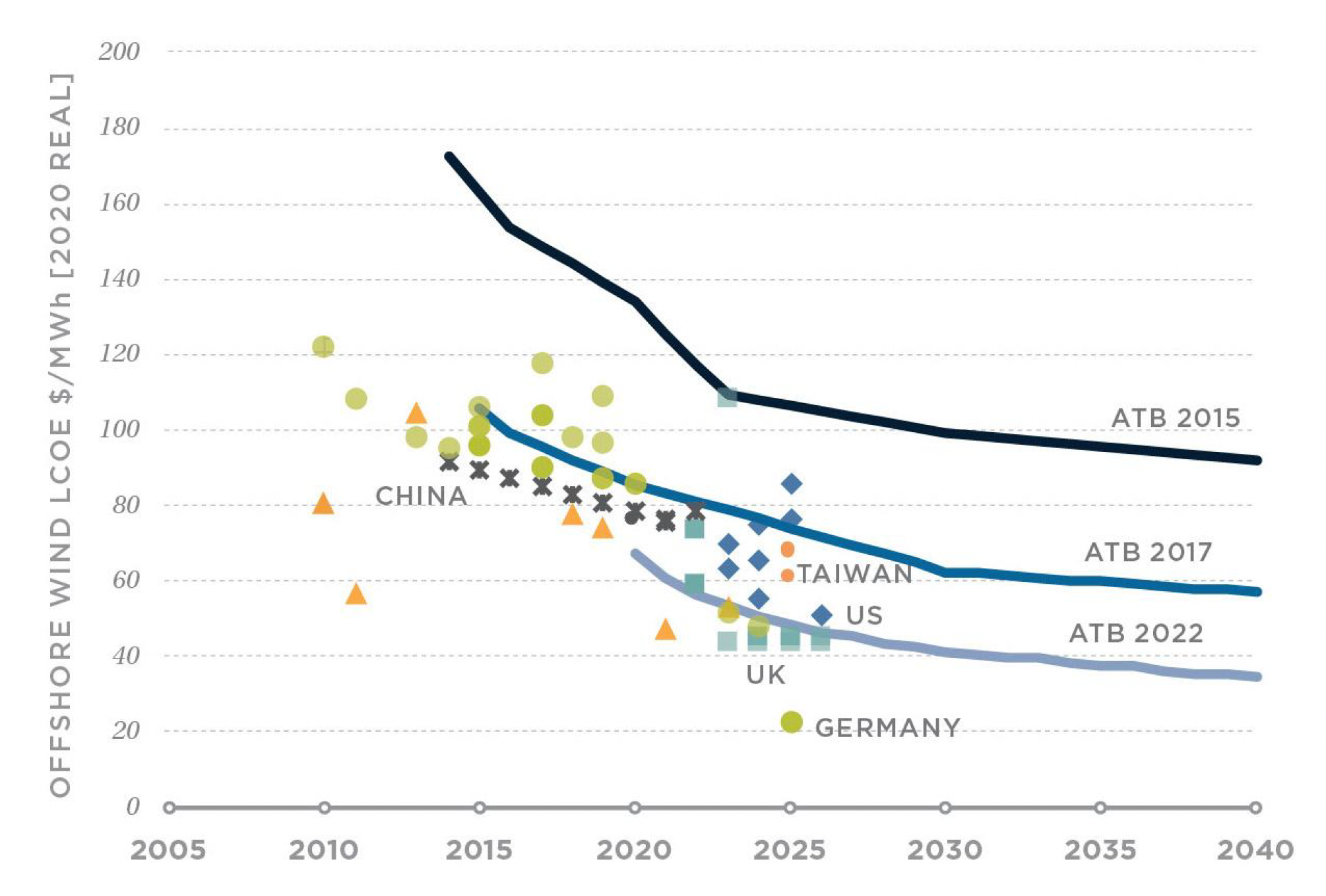

Is The Offshore Wind Boom Over? Examining The Cost Factor

Table of Contents

The Rising Costs of Offshore Wind Turbine Installation

The process of installing offshore wind turbines is incredibly complex and expensive, and costs have been rising significantly. This is due to a confluence of factors, creating substantial challenges for project developers and investors.

Increased Material Costs

The escalating prices of raw materials represent a major hurdle. Steel, concrete, and the specialized components used in turbine construction have seen dramatic price increases. This isn't simply a matter of market fluctuations; supply chain disruptions stemming from geopolitical events and global inflation have exacerbated the problem, pushing offshore wind energy costs higher. The impact of the war in Ukraine, for example, has significantly affected the availability and price of certain crucial materials.

- Higher steel prices: Steel forms a significant portion of turbine construction, making it highly sensitive to price swings.

- Longer lead times for components: Delays in sourcing parts lead to project delays and increased overall costs.

- Increased transportation costs: The cost of shipping materials to offshore construction sites has also risen considerably.

Specialized Vessels and Installation Challenges

Offshore wind turbine installation demands highly specialized vessels and a skilled workforce, contributing significantly to the cost of offshore wind farms. These specialized vessels, capable of operating in harsh marine environments, come with hefty charter rates. Furthermore, the technical challenges of working in deep waters and unpredictable weather conditions often lead to delays and cost overruns. The need for experienced crews adds another layer of expense, especially given the intense training required for this demanding work.

- High vessel charter rates: Specialized installation vessels are expensive to charter.

- Specialized crew training costs: Training highly skilled personnel for offshore installation is costly.

- Weather-related delays: Inclement weather can cause significant project delays, increasing costs.

Grid Connection and Infrastructure Limitations

Connecting offshore wind farms to the onshore grid presents a significant hurdle, often involving substantial infrastructure upgrades and considerable expense. This is a critical factor influencing the overall cost of offshore wind.

Expensive Grid Upgrades and Transmission Lines

The integration of offshore wind energy into existing power grids frequently necessitates significant upgrades to onshore infrastructure. This involves substantial investment in new substations and, most importantly, the laying of long submarine cables to transmit power from the offshore wind farm to the mainland grid. The regulatory hurdles and lengthy permitting processes involved only add to the complexity and cost.

- Cost of onshore grid upgrades: Upgrading existing infrastructure to handle increased capacity is expensive.

- Permitting delays and costs: Navigating regulatory processes can lead to prolonged delays and increased costs.

- High cost of submarine cable installation: Laying submarine cables is a technically demanding and expensive operation.

Geographical Constraints and Transmission Distance

The distance between offshore wind farms and the onshore grid is a critical factor determining the cost of energy transmission. The further the distance, the longer and more expensive the submarine cables required. Moreover, energy loss during transmission over long distances also needs to be considered. The optimal location for an offshore wind farm must consider not just wind resources but also the proximity to the grid to minimize these costs.

- Increased cable length increases costs: Longer cables directly translate to higher installation and material costs.

- Energy losses during transmission: Energy is lost during transmission over long distances, reducing overall efficiency.

- Difficulties in choosing optimal cable routes: Finding suitable and cost-effective cable routes can be challenging.

Operational and Maintenance Costs

The operational and maintenance (O&M) costs associated with offshore wind farms represent a substantial long-term expense. The remote and often harsh marine environment presents unique challenges.

Accessibility and Remote Location Challenges

Maintaining and repairing offshore wind turbines requires specialized vessels and highly skilled technicians, adding to the overall cost of offshore wind. The remote locations of many offshore wind farms increase the logistical and transportation costs significantly. This means higher travel and accommodation expenses for technicians and more costly deployment of specialized equipment. Regular preventative maintenance is crucial to minimize costly breakdowns.

- High cost of specialized maintenance vessels: Specialized vessels are needed for maintenance and repairs.

- Travel and accommodation costs for technicians: Getting technicians to remote locations is costly.

- Potential for costly repairs due to harsh marine environments: Repairs in harsh conditions are expensive and complex.

Long-Term O&M Planning and Budgeting

The long lifespan of offshore wind turbines necessitates meticulous long-term operational and maintenance planning. Accurate cost forecasting for the entire operational life of the wind farm is crucial for ensuring its financial viability. Innovation in O&M strategies and technologies is essential to reducing these costs over time. This might involve using drones for inspections, predictive maintenance techniques, and advancements in turbine design for greater durability.

- Accurate cost forecasting over decades: Accurately predicting O&M costs over the turbine's lifetime is challenging.

- Technological advancements for reduced maintenance: New technologies can help reduce the need for maintenance.

- Developing efficient O&M strategies: Efficient planning and strategies are vital for cost control.

Conclusion

While the rising costs of offshore wind are a serious consideration, declaring the boom "over" would be premature. The future of this vital renewable energy source hinges on effectively addressing these cost challenges through innovative solutions. This includes investing in research and development to create more cost-effective turbine designs, efficient grid connection technologies, and advanced O&M strategies. Streamlining regulatory processes and improving project planning are equally critical. The transition to a sustainable energy future relies heavily on the continued development of offshore wind technology. Overcoming these cost obstacles will be instrumental in unlocking the full potential of offshore wind as a cleaner, more sustainable energy source. Let’s continue to explore innovative ways to make offshore wind a more cost-effective and viable contributor to the global energy transition.

Featured Posts

-

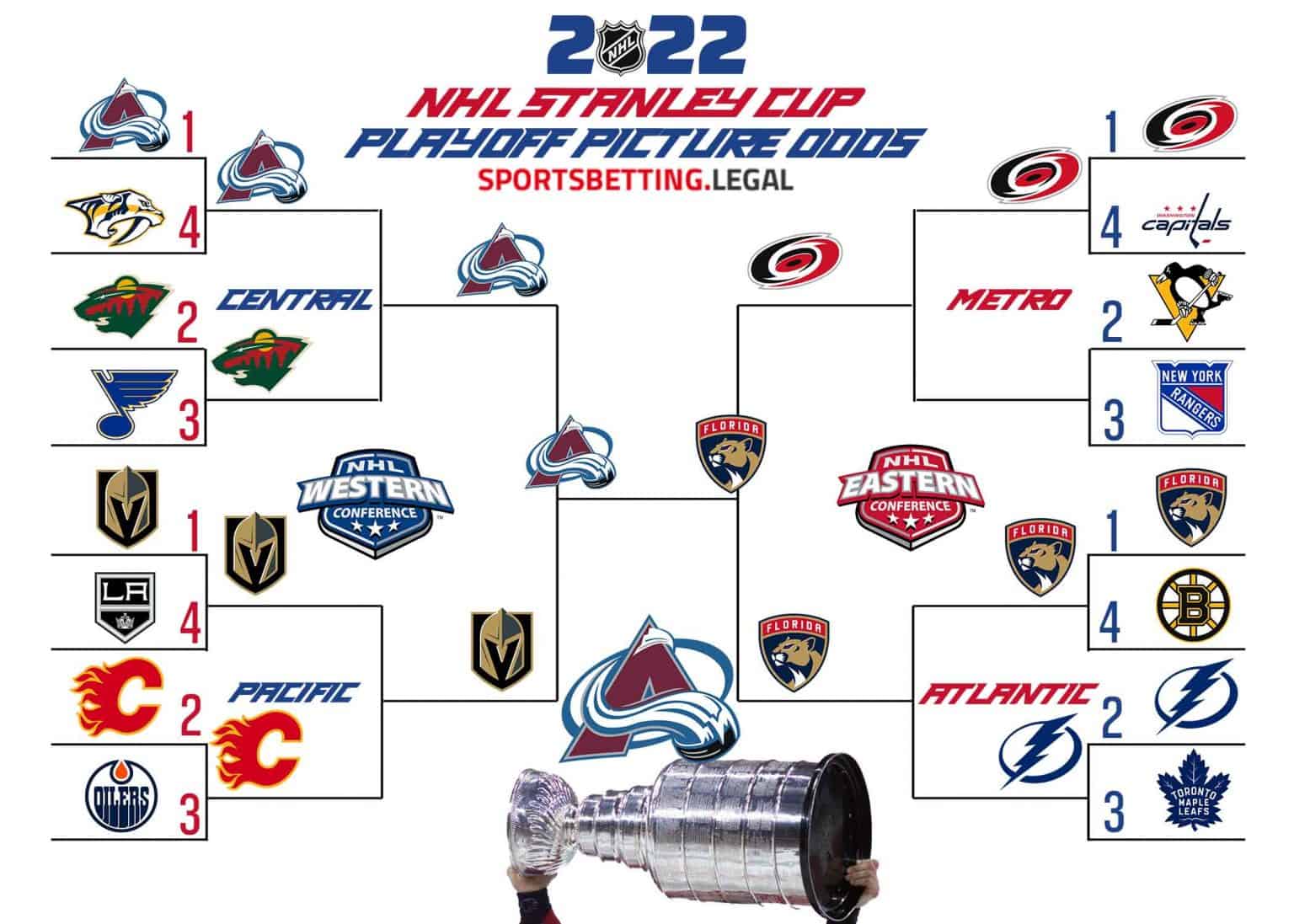

Nhl Playoffs 2024 Who Will Win The Stanley Cup

May 04, 2025

Nhl Playoffs 2024 Who Will Win The Stanley Cup

May 04, 2025 -

Thunderbolts A Deep Dive Into Marvels Latest Team

May 04, 2025

Thunderbolts A Deep Dive Into Marvels Latest Team

May 04, 2025 -

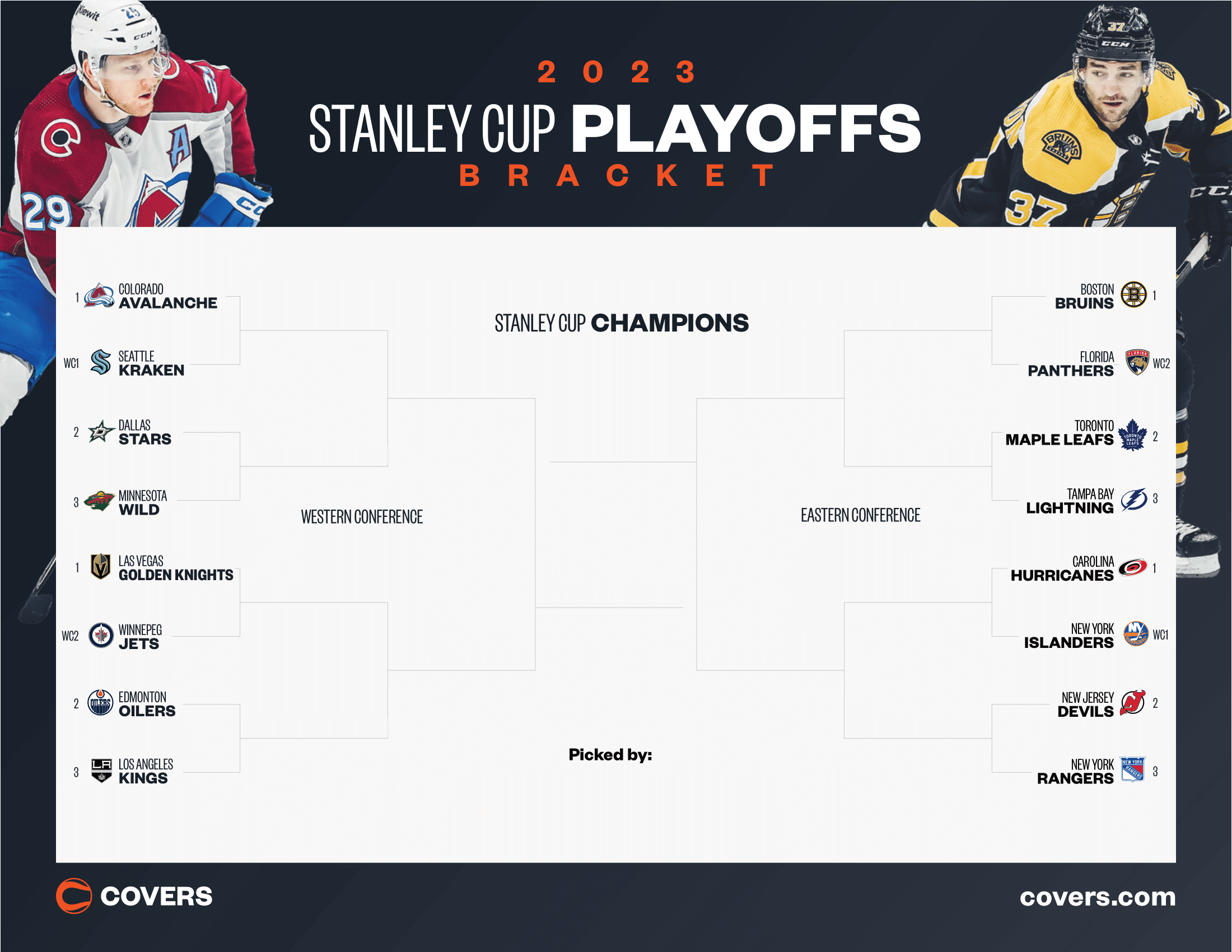

Analyzing The Nhl Playoff Standings Your Guide To Showdown Saturday

May 04, 2025

Analyzing The Nhl Playoff Standings Your Guide To Showdown Saturday

May 04, 2025 -

Legal Implications Of Selling Banned Chemicals On E Bay Section 230 At Stake

May 04, 2025

Legal Implications Of Selling Banned Chemicals On E Bay Section 230 At Stake

May 04, 2025 -

April Employment Report U S Job Growth And Unemployment Data

May 04, 2025

April Employment Report U S Job Growth And Unemployment Data

May 04, 2025

Latest Posts

-

Ufc 314 Mitchell Silva Press Conference Marked By Heated Exchange And Allegations Of Cursing

May 04, 2025

Ufc 314 Mitchell Silva Press Conference Marked By Heated Exchange And Allegations Of Cursing

May 04, 2025 -

Ufc 314 Star Studded Lineup Suffers Setback With Neal Prates Fight Cancellation

May 04, 2025

Ufc 314 Star Studded Lineup Suffers Setback With Neal Prates Fight Cancellation

May 04, 2025 -

Bryce Mitchell Calls Out Jean Silva For Profanity At Ufc 314 Press Conference

May 04, 2025

Bryce Mitchell Calls Out Jean Silva For Profanity At Ufc 314 Press Conference

May 04, 2025 -

Ufc 314 Neal Vs Prates Cancellation Shakes Up Star Studded Card

May 04, 2025

Ufc 314 Neal Vs Prates Cancellation Shakes Up Star Studded Card

May 04, 2025 -

The Paddy Pimblett Dustin Poirier Retirement Debate

May 04, 2025

The Paddy Pimblett Dustin Poirier Retirement Debate

May 04, 2025