Manufacturers Prioritize Cybersecurity: A 63.5% Investment Surge

Table of Contents

The Rising Threat Landscape for Manufacturers

Manufacturers are facing a diverse and ever-evolving range of cyber threats. These attacks are no longer limited to IT systems; they directly target the operational technology (OT) infrastructure that controls physical processes in factories and production lines. The consequences can be devastating.

-

Increased ransomware attacks targeting industrial control systems (ICS): Ransomware attacks are becoming increasingly sophisticated, targeting ICS to disrupt production, leading to significant financial losses and reputational damage. A successful attack can halt entire production lines, causing massive downtime and impacting supply chains.

-

Supply chain vulnerabilities exploited to compromise manufacturing processes: Cybercriminals are exploiting weaknesses in the supply chain to gain access to manufacturing environments. This could involve compromising a supplier's systems to then infiltrate the manufacturer's network.

-

Data breaches leading to loss of sensitive intellectual property and customer data: Data breaches can result in the loss of valuable intellectual property, sensitive customer data, and trade secrets, leading to significant financial and legal repercussions. Regulations like GDPR demand stringent data protection, making robust cybersecurity crucial.

-

Industrial espionage aiming to steal proprietary manufacturing processes: Competitors may engage in industrial espionage to steal valuable manufacturing processes and intellectual property, giving them a significant competitive edge.

Key Areas of Cybersecurity Investment in Manufacturing

The 63.5% increase in investment reflects a multi-faceted approach to bolstering manufacturing cybersecurity. Manufacturers are prioritizing several key areas:

-

Enhanced endpoint security for industrial control systems (ICS) and operational technology (OT) devices: This includes deploying advanced endpoint detection and response (EDR) solutions specifically designed for industrial environments to monitor and protect ICS and OT devices from malware and unauthorized access.

-

Improved network security through segmentation, firewalls, and intrusion detection/prevention systems: Network segmentation isolates critical systems from less critical ones, limiting the impact of a breach. Firewalls and intrusion detection/prevention systems provide additional layers of defense against malicious network activity.

-

Secure cloud adoption for manufacturing data and applications: Many manufacturers are migrating data and applications to the cloud, but this requires secure cloud strategies including data encryption, access control, and robust identity and access management (IAM) solutions.

-

Comprehensive security awareness training for employees at all levels: Human error remains a significant vulnerability. Training programs educate employees about cybersecurity threats and best practices, reducing the risk of phishing attacks and other social engineering tactics.

-

Investment in threat intelligence and vulnerability management programs: Proactive threat intelligence helps manufacturers anticipate and prepare for emerging threats. Vulnerability management ensures that systems are regularly patched and updated to address known vulnerabilities.

The Benefits of Robust Manufacturing Cybersecurity

Investing in robust manufacturing cybersecurity isn't just about mitigating risks; it offers significant tangible benefits, contributing to a strong ROI:

-

Minimizing downtime caused by cyberattacks: Robust cybersecurity significantly reduces the likelihood and impact of downtime caused by cyberattacks, protecting production schedules and revenue streams.

-

Improved compliance with industry regulations (e.g., NIST, GDPR): Strong cybersecurity measures demonstrate compliance with relevant industry regulations and standards, avoiding potential penalties and legal issues.

-

Enhanced reputation and customer trust: Demonstrating a commitment to cybersecurity builds trust with customers and partners, enhancing the company's reputation and brand image.

-

Gaining a competitive advantage by demonstrating a strong security posture: In today's increasingly interconnected world, a strong cybersecurity posture is a key differentiator, attracting customers and investors.

-

Protecting valuable intellectual property and sensitive data: Robust cybersecurity safeguards valuable intellectual property, sensitive customer data, and trade secrets from theft or unauthorized access.

Strategies for Implementing Effective Cybersecurity Measures

Implementing effective cybersecurity requires a strategic approach:

-

Conduct a thorough risk assessment: Identify vulnerabilities and prioritize security improvements based on their potential impact.

-

Develop a robust security architecture: Design a layered security architecture that incorporates multiple security controls to defend against various threats.

-

Create and regularly test an incident response plan: Establish procedures for handling security incidents to minimize damage and ensure business continuity.

-

Implement a comprehensive vulnerability management program: Regularly scan for vulnerabilities, prioritize patching, and monitor for emerging threats.

Conclusion

The 63.5% surge in manufacturing cybersecurity investment underscores a critical shift in the industry's approach to security. Manufacturers are increasingly recognizing the devastating consequences of cyberattacks and the importance of proactive measures to protect their operations. By investing in key areas like endpoint security, network security, and employee training, manufacturers can mitigate risks, improve compliance, enhance their reputation, and gain a competitive edge. Don't wait until a cyberattack impacts your bottom line. Prioritize manufacturing cybersecurity today and protect your business. Learn more about specific cybersecurity solutions tailored for manufacturers to ensure your operations are resilient against the ever-evolving threat landscape.

Featured Posts

-

Gaza Hostage Crisis The Nightmare Continues For Families

May 13, 2025

Gaza Hostage Crisis The Nightmare Continues For Families

May 13, 2025 -

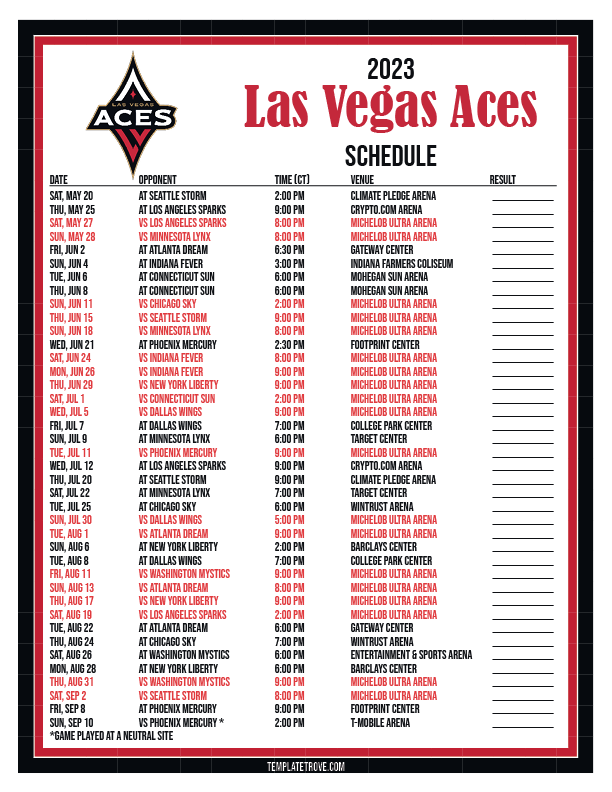

Las Vegas Aces Training Camp Roster Update And Forward Cut

May 13, 2025

Las Vegas Aces Training Camp Roster Update And Forward Cut

May 13, 2025 -

Fylm Zndgy Namh Ay Aywl Knywl Dy Kapryw W Brwdy Dr Mdhakrat

May 13, 2025

Fylm Zndgy Namh Ay Aywl Knywl Dy Kapryw W Brwdy Dr Mdhakrat

May 13, 2025 -

Free Live Streams Manchester United Tottenham Hotspur And Lyon In The Uefa Europa League

May 13, 2025

Free Live Streams Manchester United Tottenham Hotspur And Lyon In The Uefa Europa League

May 13, 2025 -

Cassie And Alex Fines Mob Land Premiere A Look At Their Red Carpet Debut

May 13, 2025

Cassie And Alex Fines Mob Land Premiere A Look At Their Red Carpet Debut

May 13, 2025

Latest Posts

-

Pochemu Skarlett Yokhansson Ne Delaet Selfi Obyasnenie Aktrisy

May 13, 2025

Pochemu Skarlett Yokhansson Ne Delaet Selfi Obyasnenie Aktrisy

May 13, 2025 -

Colin Josts Lower Salary Compared To Scarlett Johansson A Look At Their Finances

May 13, 2025

Colin Josts Lower Salary Compared To Scarlett Johansson A Look At Their Finances

May 13, 2025 -

Black Widow To Telos Mias Epoxis Gia Ti Skarlet Gioxanson

May 13, 2025

Black Widow To Telos Mias Epoxis Gia Ti Skarlet Gioxanson

May 13, 2025 -

Skarlett Yokhansson Pravda O Nezhelanii Delat Selfi S Poklonnikami

May 13, 2025

Skarlett Yokhansson Pravda O Nezhelanii Delat Selfi S Poklonnikami

May 13, 2025 -

I Skarlet Gioxanson Apoxaireta Tin Black Widow

May 13, 2025

I Skarlet Gioxanson Apoxaireta Tin Black Widow

May 13, 2025