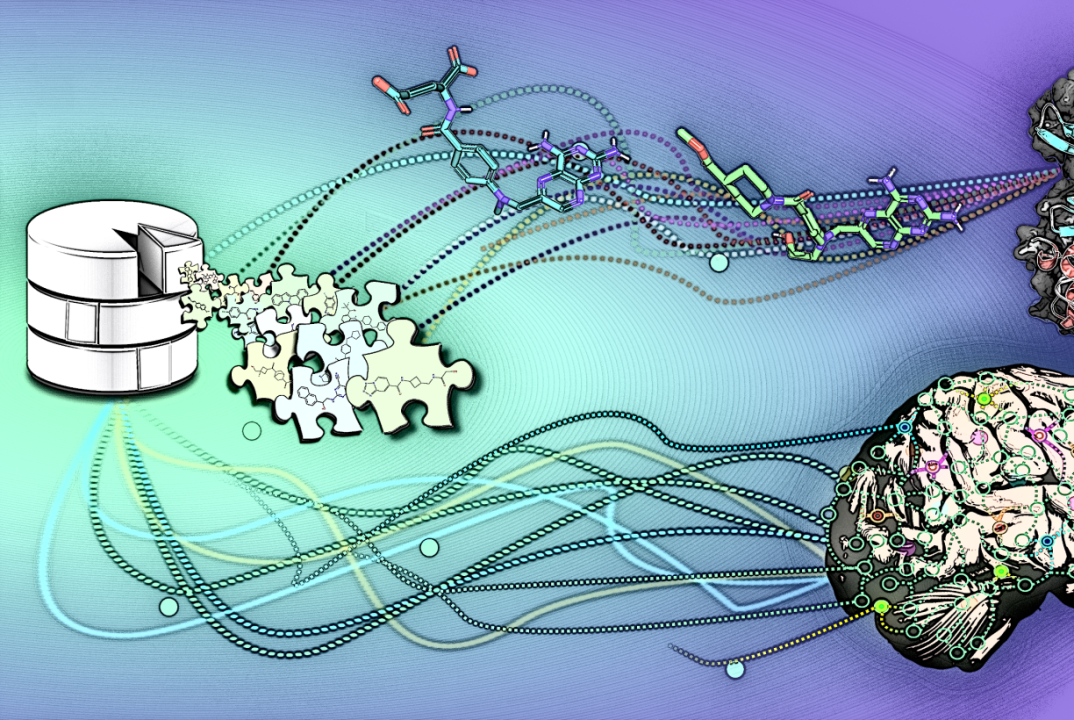

Orbital Crystallography: Revolutionizing Drug Design And Production

Table of Contents

Enhanced Accuracy in Drug Design

Orbital crystallography provides an unparalleled level of detail in understanding molecular interactions, the very foundation of drug efficacy. This heightened accuracy stems from its ability to map electron density within molecules with extraordinary precision.

Understanding Molecular Interactions:

- Improved prediction of drug efficacy: By visualizing the intricate interactions between a drug molecule and its target, orbital crystallography allows for more accurate predictions of a drug's effectiveness. This reduces the reliance on trial-and-error experimentation.

- Identification of potential side effects: The detailed electron density maps reveal potential interactions with off-target molecules, enabling the early identification and mitigation of potential side effects. This is crucial for improving drug safety and reducing the risk of adverse events.

- Optimization of drug-target binding: Orbital crystallography facilitates the optimization of drug design to enhance binding affinity and selectivity for the target, leading to more potent and specific drugs. This precise understanding of bonding allows for the fine-tuning of drug structure for improved performance.

The electron density mapping process reveals crucial details about molecular structure, including bond lengths, angles, and electron distribution. This information is essential for understanding how molecules interact and behave within a biological system.

Predicting Drug Metabolism and Pharmacokinetics (DMPK):

A thorough understanding of molecular interactions is pivotal in predicting DMPK properties. Orbital crystallography enables researchers to:

- Improve prediction of drug clearance: By analyzing the interaction of a drug molecule with metabolic enzymes, orbital crystallography allows for better prediction of how quickly the drug will be cleared from the body.

- Enhance bioavailability prediction: This technique helps in predicting the fraction of the administered drug that reaches the systemic circulation, a critical factor determining a drug's effectiveness.

- Accurately predict drug half-life: Orbital crystallography contributes to more precise estimations of how long a drug remains active in the body, leading to better dosing regimens.

Reduced reliance on extensive and costly in vivo testing is a significant advantage, accelerating the overall drug development process and lowering costs. Studies have shown improved DMPK prediction using orbital crystallography compared to traditional methods, resulting in fewer failures in later stages of drug development.

Accelerated Drug Development Process

Orbital crystallography's enhanced accuracy translates directly into a significantly faster and more efficient drug development pipeline.

Reduced Experimental Trial and Error:

The precision offered by orbital crystallography minimizes the need for extensive trial-and-error experimentation. This leads to:

- Faster identification of lead compounds: Researchers can quickly identify promising drug candidates, saving valuable time and resources.

- Reduced time to market: The accelerated development process significantly reduces the time it takes to bring a new drug to market, making it available to patients sooner.

- Lower development costs: Fewer failed experiments and a streamlined development process translate into considerable cost savings.

Traditional drug discovery often involves many years of experimentation, with a high percentage of candidates failing to progress to clinical trials. Orbital crystallography promises to drastically shorten this timeline.

Computer-Aided Drug Design (CADD) Integration:

Orbital crystallography data integrates seamlessly with CADD workflows, accelerating virtual screening and optimization. This integration enables:

- Improved virtual screening accuracy: The detailed molecular information improves the accuracy of virtual screening, allowing researchers to prioritize the most promising candidates for further investigation.

- More efficient lead optimization: Orbital crystallography data guides the optimization of lead compounds, improving their potency and reducing side effects.

- Reduced reliance on expensive laboratory synthesis: By prioritizing promising candidates through virtual screening, the need for expensive laboratory synthesis is minimized.

Several leading CADD platforms are actively incorporating orbital crystallography data, demonstrating its value in accelerating and improving drug design.

Cost-Effective Drug Production

Beyond accelerating development, orbital crystallography contributes to more cost-effective drug production.

Optimized Synthesis and Purification:

Orbital crystallography guides the optimization of synthesis and purification processes:

- Improved reaction efficiency: This leads to higher yields of the desired drug product.

- Reduced material consumption: More efficient processes minimize waste and reduce the need for expensive starting materials.

- Lower overall production costs: Optimized processes lead to significant reductions in manufacturing costs.

Waste reduction is a critical aspect of sustainable drug production, and orbital crystallography significantly contributes to these efforts.

Scalability and Industrial Applications:

Orbital crystallography techniques are scalable and adaptable to industrial-scale drug production:

- Applicability to high-throughput screening: It can be used to analyze large numbers of compounds quickly and efficiently.

- Automation potential: The technique is amenable to automation, further enhancing efficiency and scalability.

- Integration into existing manufacturing processes: Orbital crystallography data can easily be incorporated into existing drug manufacturing workflows.

The potential for personalized medicine, tailoring drug design to individual patient needs, is further enhanced by orbital crystallography’s detailed molecular insights.

Conclusion:

Orbital crystallography offers a transformative approach to drug design and production. Its key advantages—enhanced accuracy in understanding molecular interactions, accelerated drug development, and cost-effective manufacturing—promise to revolutionize the pharmaceutical industry. Ongoing research continues to expand its capabilities and applications.

Discover how orbital crystallography can revolutionize your drug development process. Learn more today!

Featured Posts

-

Trucking News And Analysis Big Rig Rock Report 3 12 99 5 The Fox

May 23, 2025

Trucking News And Analysis Big Rig Rock Report 3 12 99 5 The Fox

May 23, 2025 -

Memorial Day 2025 Store Hours Check Florida Grocery Store Availability

May 23, 2025

Memorial Day 2025 Store Hours Check Florida Grocery Store Availability

May 23, 2025 -

Savannah Guthries Unexpected Co Host Change A Mid Week Update

May 23, 2025

Savannah Guthries Unexpected Co Host Change A Mid Week Update

May 23, 2025 -

The Who At 80 A Look At Life After Rock N Roll

May 23, 2025

The Who At 80 A Look At Life After Rock N Roll

May 23, 2025 -

Cambios En La Citacion De Instituto Implicaciones Para El Partido Contra Lanus

May 23, 2025

Cambios En La Citacion De Instituto Implicaciones Para El Partido Contra Lanus

May 23, 2025

Latest Posts

-

The Story Behind The Couples Fight Over Joe Jonas

May 23, 2025

The Story Behind The Couples Fight Over Joe Jonas

May 23, 2025 -

Joe Jonass Mature Reaction To A Couples Argument

May 23, 2025

Joe Jonass Mature Reaction To A Couples Argument

May 23, 2025 -

How Joe Jonas Handled A Couples Fight About Him

May 23, 2025

How Joe Jonas Handled A Couples Fight About Him

May 23, 2025 -

Jonathan Groff Could He Win A Tony Award For Just In Time

May 23, 2025

Jonathan Groff Could He Win A Tony Award For Just In Time

May 23, 2025 -

Jonathan Groff And Just In Time A Tony Awards Prediction

May 23, 2025

Jonathan Groff And Just In Time A Tony Awards Prediction

May 23, 2025