Steel Industry Decarbonization: The Promise Of Eramet's EraLow

Table of Contents

Understanding the eraLow Process

Eramet's eraLow process represents a significant advancement in steelmaking, offering a viable solution to the industry's substantial carbon emissions. Its innovative approach promises to reshape the future of sustainable steel production.

Key Features of eraLow:

- Direct Reduced Iron (DRI) with Hydrogen: Unlike traditional blast furnaces reliant on coke (a significant CO2 source), eraLow directly reduces iron ore using hydrogen. This significantly reduces CO2 emissions, moving towards green steel production.

- Renewable Energy Integration: The hydrogen used in the eraLow process is ideally sourced from renewable energy sources, such as wind and solar power. This minimizes the carbon intensity of the entire process, leading to near-zero carbon steel.

- Near-Zero Carbon Steel Production: The ultimate goal of eraLow is to achieve near-zero carbon steel production, aligning with global efforts to mitigate climate change and reduce reliance on fossil fuels in industrial processes.

- Circular Economy Principles: eraLow incorporates circular economy principles by optimizing resource utilization and minimizing waste throughout the production process. This contributes to a more sustainable and efficient steel supply chain.

Technological Advantages of eraLow:

- Enhanced Efficiency: Compared to traditional steelmaking methods, eraLow boasts higher efficiency, optimizing resource consumption and reducing overall production costs.

- Superior Product Quality: The process leads to improved product quality and consistency, meeting the stringent demands of modern steel applications.

- Reduced Energy Consumption: eraLow’s innovative design leads to lower energy consumption compared to blast furnace methods, contributing to reduced operational costs and a smaller environmental footprint.

- Scalability and Future Demand: Eramet has designed eraLow with scalability in mind, ensuring it can meet the growing global demand for green steel and sustainable materials in the future.

Environmental Impact of eraLow:

- Greenhouse Gas Reduction: The primary environmental benefit of eraLow is the substantial reduction in greenhouse gas emissions, contributing significantly to reducing the steel industry's carbon footprint.

- Pollution Minimization: By utilizing hydrogen instead of coke, the process minimizes air and water pollution, creating a cleaner and safer production environment.

- Sustainable Steel Supply Chain: eraLow fosters the development of a more sustainable steel supply chain, encouraging the use of renewable energy and resource-efficient practices throughout the industry.

- Alignment with Global Goals: The eraLow process is in alignment with global climate goals and environmental regulations, supporting international efforts towards climate neutrality.

Eramet's Commitment to Sustainable Steel Production

Eramet's dedication to sustainable steel production is evident in its significant investment and commitment to the eraLow process. This commitment reflects a broader industry shift towards green steel production and the reduction of carbon emissions.

Eramet's Role in the Green Steel Revolution:

- R&D Investment: Eramet has made significant investments in research and development for the eraLow technology, driving continuous improvement and optimization of the process.

- Industry Collaboration: Eramet actively collaborates with industry partners to accelerate the adoption of eraLow, fostering innovation and knowledge sharing across the sector.

- Infrastructure Development: The company focuses on building a robust and scalable infrastructure for eraLow deployment, ensuring its long-term viability and market penetration.

- Long-Term Vision: Eramet has a clear long-term vision for a decarbonized steel industry, making eraLow a cornerstone of its sustainable business strategy.

The Future of eraLow Deployment:

- Pilot Plant and Industrial Scale-up: Eramet is currently operating pilot plants and planning large-scale industrial deployment of the eraLow technology.

- Strategic Partnerships: The company is actively exploring partnerships and collaborations to expand eraLow's reach and accelerate its market adoption.

- Hydrogen Infrastructure Development: Eramet is addressing the challenges related to hydrogen production and infrastructure development, crucial for the long-term success of eraLow.

- Sustainable Growth Strategy: Eramet has implemented a strategic plan for sustainable growth and market expansion of eraLow, ensuring its long-term viability and impact.

The Broader Impact on the Steel Industry

The successful implementation of eraLow will have a transformative impact on the steel industry, affecting various aspects of production, consumption, and environmental sustainability.

Transforming the Steel Value Chain:

- Increased Green Steel Demand: The growing awareness of environmental issues among consumers and businesses is driving an increased demand for green steel, creating a strong market for eraLow.

- Job Creation: The transition to green steel production will likely create new job opportunities in the green steel sector, contributing to economic growth and regional development.

- Market Dynamics: Eramet's eraLow is expected to influence steel pricing and market dynamics, creating new competitive landscapes in the steel industry.

- Innovation Stimulus: The success of eraLow could spur innovation in other aspects of steel production, leading to further improvements in sustainability and efficiency.

Addressing the Challenges of Steel Decarbonization:

- Capital Investment: A major challenge is the high initial capital investment required for new decarbonization technologies like eraLow.

- Government Support: Supportive government policies and financial incentives are crucial to accelerating the adoption of sustainable steelmaking technologies.

- Hydrogen Supply Chain: The development of a robust and reliable hydrogen supply chain is essential for the widespread adoption of eraLow.

- Infrastructure Integration: Integrating eraLow technology into existing steelmaking infrastructure may require significant adaptations and investments.

Conclusion

Eramet's eraLow process presents a significant leap forward in steel industry decarbonization. Its innovative approach to direct reduction using renewable hydrogen offers a pathway to near-zero carbon steel production, addressing a crucial environmental challenge. The technological advantages, combined with Eramet's commitment to sustainability, position eraLow as a key player in the green steel revolution. The transition to sustainable steel production is a collaborative effort, and Eramet's commitment to innovation provides a vital step towards a greener, more sustainable future for the steel industry.

Call to Action: Learn more about Eramet's eraLow and its potential to reshape the future of sustainable steel production. Join the movement towards decarbonized steel – explore the possibilities of eraLow and green steel solutions today!

Featured Posts

-

Eurovizijos Atidarymo Ceremonija Muzika Protestai Ir Saunos Bazelyje

May 14, 2025

Eurovizijos Atidarymo Ceremonija Muzika Protestai Ir Saunos Bazelyje

May 14, 2025 -

2 4 Mayis 2025 Tarim Kredi Koop Ta Gida Ve Temizlik Ueruenlerinde Firsatlar

May 14, 2025

2 4 Mayis 2025 Tarim Kredi Koop Ta Gida Ve Temizlik Ueruenlerinde Firsatlar

May 14, 2025 -

Eurojackpot Tulokset Tarkista Numerot Ilta Sanomista

May 14, 2025

Eurojackpot Tulokset Tarkista Numerot Ilta Sanomista

May 14, 2025 -

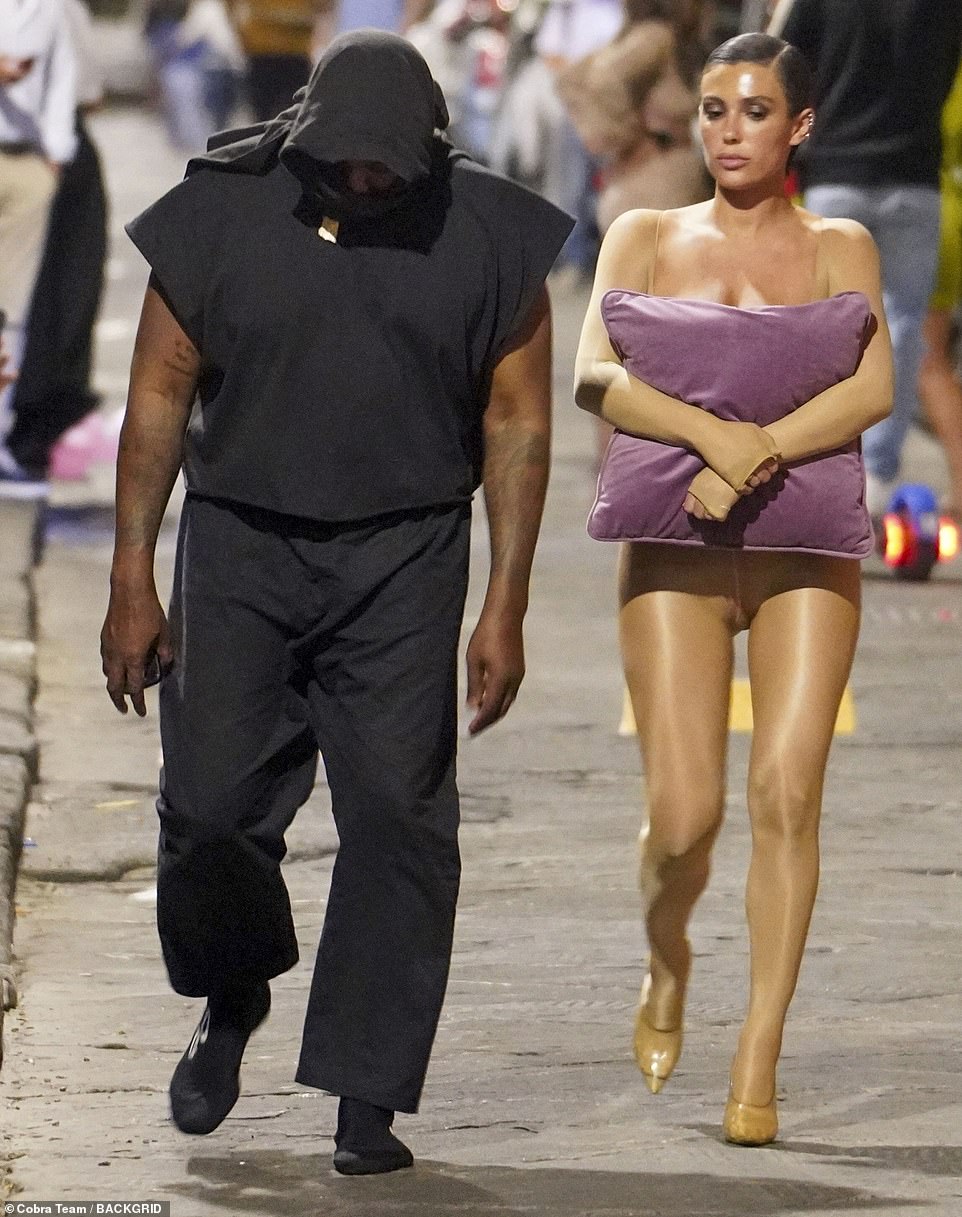

Bianca Censoris Fears An Exclusive Look At Her Relationship With Kanye West

May 14, 2025

Bianca Censoris Fears An Exclusive Look At Her Relationship With Kanye West

May 14, 2025 -

Digital And Physical Release Of Captain America Brave New World Dates Prices And Where To Watch

May 14, 2025

Digital And Physical Release Of Captain America Brave New World Dates Prices And Where To Watch

May 14, 2025