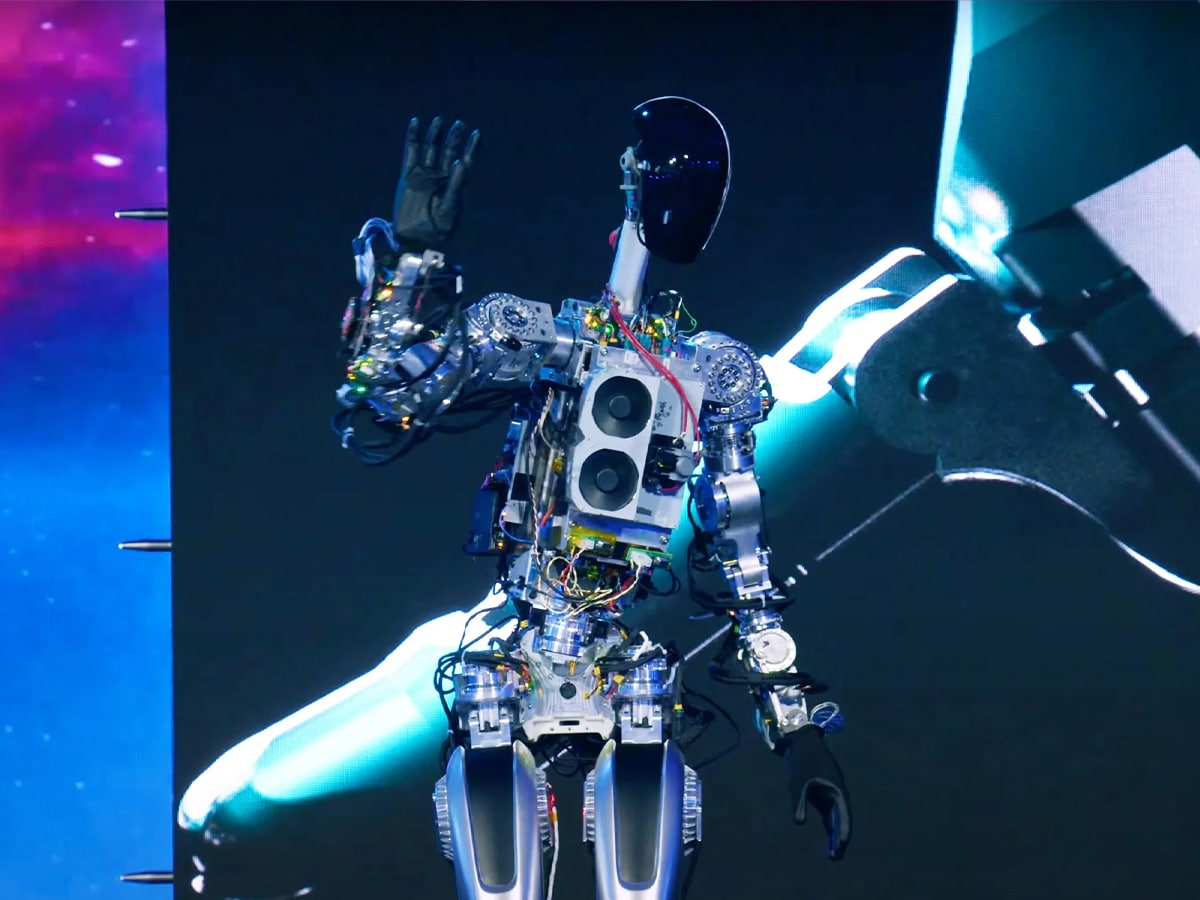

Tesla's Optimus Robot: China's Rare Earth Restrictions Cause Delays

Table of Contents

China's Dominance in Rare Earth Element Production

China's control over the rare earth element market is undeniable. These minerals, vital for numerous advanced technologies, are not evenly distributed globally. Understanding China's dominance is key to grasping the Optimus robot delays.

- China controls over 60% of global rare earth mining and processing. This gives them immense leverage in setting prices and controlling the global supply.

- Rare earth elements like neodymium, dysprosium, and praseodymium are critical. They are essential components in powerful magnets, crucial for a wide range of applications, including electric vehicles and, importantly, robots.

- China's recent export restrictions are strategic. These restrictions aim to secure domestic resources for their own technological advancements, prioritizing their own industries. This creates significant challenges for companies like Tesla reliant on these materials.

- Global rare earth supply chains are vulnerable. The concentration of production in China creates a single point of failure, making global supply chains susceptible to geopolitical instability and policy changes.

The Role of Rare Earth Elements in Optimus Robot Production

The Optimus robot, with its intricate movements and advanced capabilities, relies heavily on components containing rare earth elements. The impact of restricted supply is directly felt in the production process.

- Neodymium magnets are essential for Optimus robot actuators and servo motors. These magnets are critical for the precise and powerful movements required for the robot's intended functions. Without a consistent supply of high-quality neodymium magnets, production is significantly hampered.

- Robot actuators require high-performance motors. These motors, in turn, depend on strong, reliable neodymium magnets for optimal performance. Any disruption to the supply chain directly impacts the robot's functionality.

- Precision manufacturing relies on a consistent supply of components. The intricate mechanisms within the Optimus robot demand high-precision parts, making the timely supply of rare earth-based components absolutely critical.

- Tesla's reliance on these components highlights its vulnerability. This dependence on a single geopolitical source for crucial components underscores the risk inherent in relying on a concentrated supply chain.

Impact of Delays on Tesla's Automation Strategy

The delays impacting Optimus robot production have wider implications for Tesla's overall automation strategy and its manufacturing goals.

- Tesla's ambitious factory automation plans are hindered. The Optimus robot was intended to play a key role in automating Tesla's Gigafactories, boosting production efficiency and lowering manufacturing costs. Delays in robot development directly impact these plans.

- Reduced production efficiency could affect Tesla's electric vehicle output. The lack of automated processes could lead to slower production rates and potentially impact Tesla's ability to meet growing demand.

- The delay impacts Tesla's competitiveness. The robotics market is rapidly evolving, and delays in Optimus's rollout could put Tesla at a disadvantage compared to competitors with more readily available automation solutions.

- Tesla may need to explore alternative strategies. This includes exploring alternative sourcing options for rare earth elements or potentially revising its automation roadmap to lessen its dependence on the Optimus robot in the short term.

Exploring Alternative Sourcing Options for Rare Earth Elements

Tesla and other companies are actively investigating alternative strategies to mitigate the risks associated with relying on China for rare earth elements.

- Rare earth recycling is gaining traction. Recycling end-of-life products containing rare earth elements can help reduce reliance on primary mining.

- Development of substitute materials is ongoing. Research into alternative materials that can perform similar functions to those currently reliant on rare earth elements is crucial.

- Sustainable sourcing practices are essential. Companies are increasingly focusing on environmentally responsible mining practices to ensure a long-term supply of rare earth elements.

- Diversifying supply chains is paramount. Reducing dependence on any single source of rare earth elements is crucial for ensuring supply chain resilience.

Conclusion

The delays in Tesla's Optimus robot project highlight the crucial role of China's rare earth element policies in shaping global technology supply chains. The reliance on neodymium magnets reveals the vulnerability of advanced robotics to geopolitical factors. Diversification of supply chains and exploration of alternative materials are essential steps for mitigating future risks.

Call to Action: Stay informed about the evolving landscape of rare earth element supply and its impact on the future of the Tesla Optimus robot and the wider robotics industry. Follow our updates on the latest developments regarding the Tesla Optimus robot and the implications of China's rare earth restrictions. Understanding these dynamics is critical for navigating the complexities of the global technology market.

Featured Posts

-

Ftc To Appeal Microsofts Activision Blizzard Deal Faces New Hurdle

Apr 24, 2025

Ftc To Appeal Microsofts Activision Blizzard Deal Faces New Hurdle

Apr 24, 2025 -

Powell Job Security Fuels Us Stock Futures Increase

Apr 24, 2025

Powell Job Security Fuels Us Stock Futures Increase

Apr 24, 2025 -

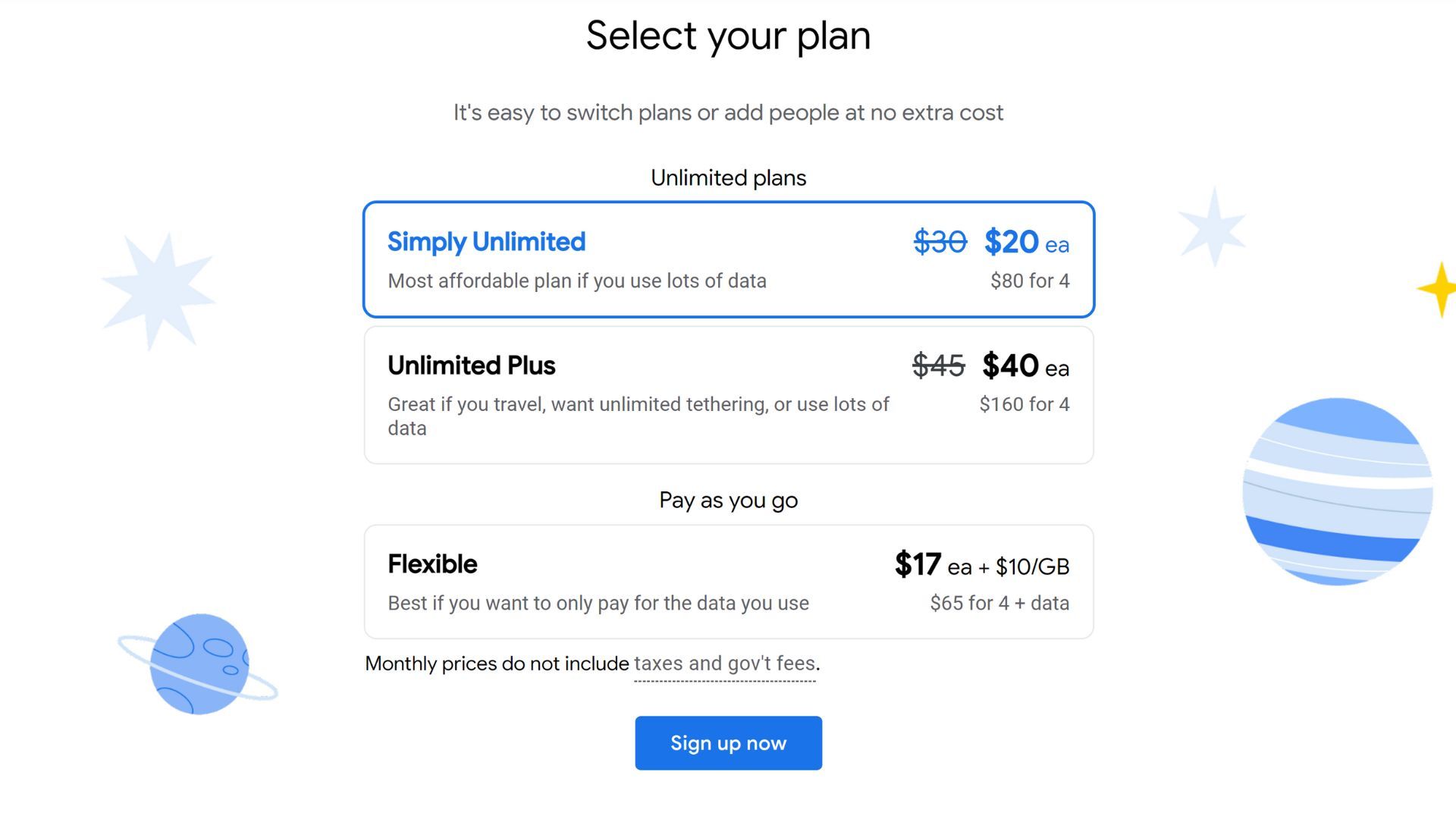

35 Month Unlimited Data Google Fis Competitive Offering

Apr 24, 2025

35 Month Unlimited Data Google Fis Competitive Offering

Apr 24, 2025 -

The Bold And The Beautiful Liam Hope And Lunas Upcoming Conflicts A 2 Week Preview

Apr 24, 2025

The Bold And The Beautiful Liam Hope And Lunas Upcoming Conflicts A 2 Week Preview

Apr 24, 2025 -

Facebooks Trajectory Zuckerbergs Leadership In A Changing Political Landscape

Apr 24, 2025

Facebooks Trajectory Zuckerbergs Leadership In A Changing Political Landscape

Apr 24, 2025