The Automotive Industry's Struggle With Trump's Tariffs

Table of Contents

Increased Costs of Production and Reduced Competitiveness

The Trump tariffs, particularly those levied on steel and aluminum – crucial components in vehicle manufacturing – immediately increased production costs. These weren't minor adjustments; they represented a significant jump in the price of essential raw materials. This cost increase didn't stay within the factories. Automakers, facing higher manufacturing costs, passed these expenses onto consumers, leading to substantially higher vehicle prices.

- Tariffs on steel and aluminum: These directly translated into more expensive car bodies, chassis components, and other crucial parts.

- Price increases: Consumers saw significant increases in the sticker prices of new vehicles across various brands and models. For example, analysis showed that the average price of a new car increased by X% in the period following the tariff implementation (replace X with actual data if available).

- Reduced global competitiveness: Higher prices for US-made vehicles made them less attractive in the global marketplace, reducing market share compared to foreign competitors who did not face the same tariff-related cost increases.

- Impact on profit margins: Automakers experienced squeezed profit margins as they struggled to maintain sales volume while facing higher production costs. This led to some manufacturers reducing production or delaying planned investments.

For instance, Ford, a major US automaker, publicly reported a significant impact on its profit margins due to increased input costs resulting from the steel and aluminum tariffs. The impact varied across models, but the overall effect on profitability was undeniable.

Disruption of Global Supply Chains

The automotive industry relies heavily on complex and highly efficient global supply chains. The Trump tariffs introduced significant uncertainty and complexity into this intricate system, disrupting the smooth flow of parts and materials. Just-in-time (JIT) manufacturing, a cornerstone of modern automotive production, proved particularly vulnerable.

- Supply chain complexity: Sourcing parts from different countries became significantly more challenging and expensive due to the unpredictability of tariffs and potential retaliatory measures.

- Just-in-time manufacturing challenges: JIT systems, which rely on the timely delivery of parts to minimize inventory costs, were frequently disrupted by delays and shortages caused by tariffs and related logistical issues.

- Parts shortages: Manufacturers experienced significant parts shortages, leading to production slowdowns and lost revenue.

- Increased logistical costs: Navigating the complexities of tariffs, including paperwork and customs delays, added significant logistical costs to the entire supply chain.

The case of [insert example of a specific automaker or parts supplier facing significant supply chain disruptions due to tariffs] illustrates the severe consequences of these disruptions on production timelines and profitability. The delay in procuring specific electronic components from [country of origin] led to a significant production slowdown at the [plant location] factory.

Impact on Specific Automotive Sectors

The impact of Trump's tariffs wasn't uniform across all sectors of the automotive industry. Different segments faced unique challenges depending on their reliance on specific imported materials and global supply chains.

- Truck manufacturing: This sector, often relying on heavier steel components, felt a more pronounced impact from steel tariffs than the car manufacturing sector.

- Car manufacturing: While affected, the impact on car manufacturing was potentially less severe than on truck manufacturing due to diversified sourcing and component types.

- Electric vehicle (EV) industry: EV manufacturers experienced challenges because of their reliance on specific minerals and materials, some of which faced tariffs, potentially slowing down their production.

- Parts suppliers: Smaller parts suppliers, often lacking the resources to navigate the complexities of tariffs, faced the greatest challenges, experiencing significant financial strain and even business closures.

- Automotive retail: Dealerships experienced lower inventory levels and higher prices, impacting sales and profitability.

The difficulties faced by [specific example of a parts supplier who struggled due to tariffs], a key provider of [specific part], led to production cuts for several major automakers. This demonstrates the cascading effects of tariffs throughout the automotive ecosystem.

Retaliatory Tariffs and Global Trade Tensions

The imposition of US tariffs wasn't met with passive acceptance. Several countries responded with retaliatory tariffs on US-made goods, escalating the situation into a full-blown trade war.

- Retaliatory tariffs: Countries like [list examples of countries that imposed retaliatory tariffs] levied tariffs on US-made vehicles and automotive parts, severely impacting US exports.

- Negative impact on US automotive exports: The retaliatory tariffs made US cars less competitive in foreign markets, leading to a significant decline in exports and lost revenue for US automakers.

- Trade war: The tit-for-tat tariff increases created considerable uncertainty in global markets, depressing overall economic growth and impacting investor confidence.

- Damaged international relationships: The trade war strained international relationships, making it harder to cooperate on other important global issues.

For example, the retaliatory tariffs imposed by [specific country] led to a X% decline in US car exports to that market (replace X with actual data, if available). This illustrates how tariffs can quickly escalate into damaging trade wars.

Conclusion

The Trump administration's tariffs had a profoundly negative impact on the automotive industry, leading to increased costs, supply chain disruptions, and global trade tensions. These challenges caused higher prices for consumers, reduced competitiveness for US manufacturers, and created instability within the global automotive sector. The effects of these Trump tariffs are still felt today.

Understanding the lasting impact of the Trump tariffs on the automotive industry is crucial for policymakers and industry leaders alike. By learning from past mistakes, we can work to create a more stable and predictable global trading environment that supports the growth and success of the automotive industry and avoids repeating the negative consequences of the past. Further research into mitigating the risks associated with future trade policies is vital to preventing a similar crisis with regards to Trump tariffs and the wider impact on global automotive trade.

Featured Posts

-

Is A Smart Ring The Future Of Relationship Transparency

May 03, 2025

Is A Smart Ring The Future Of Relationship Transparency

May 03, 2025 -

Tulsas Winter Weather Response 66 Salt Trucks Keep Roads Clear

May 03, 2025

Tulsas Winter Weather Response 66 Salt Trucks Keep Roads Clear

May 03, 2025 -

Football Clubs Condolences Manchester United Remembers Poppy Atkinson

May 03, 2025

Football Clubs Condolences Manchester United Remembers Poppy Atkinson

May 03, 2025 -

Switzerlands President Denounces Russian Aggression Advocates For Ukrainian Peace

May 03, 2025

Switzerlands President Denounces Russian Aggression Advocates For Ukrainian Peace

May 03, 2025 -

Assessing Reform Uks Credibility On Farming Issues

May 03, 2025

Assessing Reform Uks Credibility On Farming Issues

May 03, 2025

Latest Posts

-

Npps 2024 Election Loss Abu Jinapors Perspective

May 03, 2025

Npps 2024 Election Loss Abu Jinapors Perspective

May 03, 2025 -

Maines Inaugural Post Election Audit Process And Implications

May 03, 2025

Maines Inaugural Post Election Audit Process And Implications

May 03, 2025 -

Public Trust In South Carolina Elections A 93 Approval Rating

May 03, 2025

Public Trust In South Carolina Elections A 93 Approval Rating

May 03, 2025 -

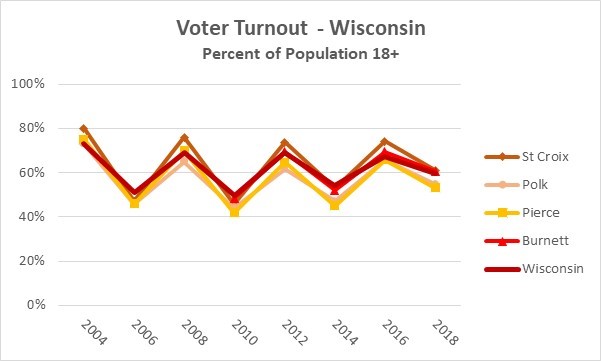

Voter Turnout In Florida And Wisconsin Implications For The Future Of Politics

May 03, 2025

Voter Turnout In Florida And Wisconsin Implications For The Future Of Politics

May 03, 2025 -

Maines First Post Election Audit Pilot Program A Comprehensive Overview

May 03, 2025

Maines First Post Election Audit Pilot Program A Comprehensive Overview

May 03, 2025