The Complexities Of Robotic Nike Sneaker Production

Table of Contents

The iconic swoosh. For decades, Nike sneakers have represented innovation and athletic performance. But behind the stylish designs and cutting-edge materials lies a complex manufacturing process, increasingly reliant on robotics. This article delves into the intricate world of robotic Nike sneaker production, exploring the challenges and advantages of this technological shift. We'll examine the automation of various stages, the impact on labor, and the future of robotic manufacturing in the footwear industry.

<h2>Automation of Sneaker Production: From Design to Delivery</h2>

Nike's journey into automated sneaker production is a multi-stage process, impacting every aspect from initial design to final delivery. The implementation of robotics has significantly streamlined operations, leading to increased efficiency and improved product quality.

<h3>Robotic Design and Prototyping</h3>

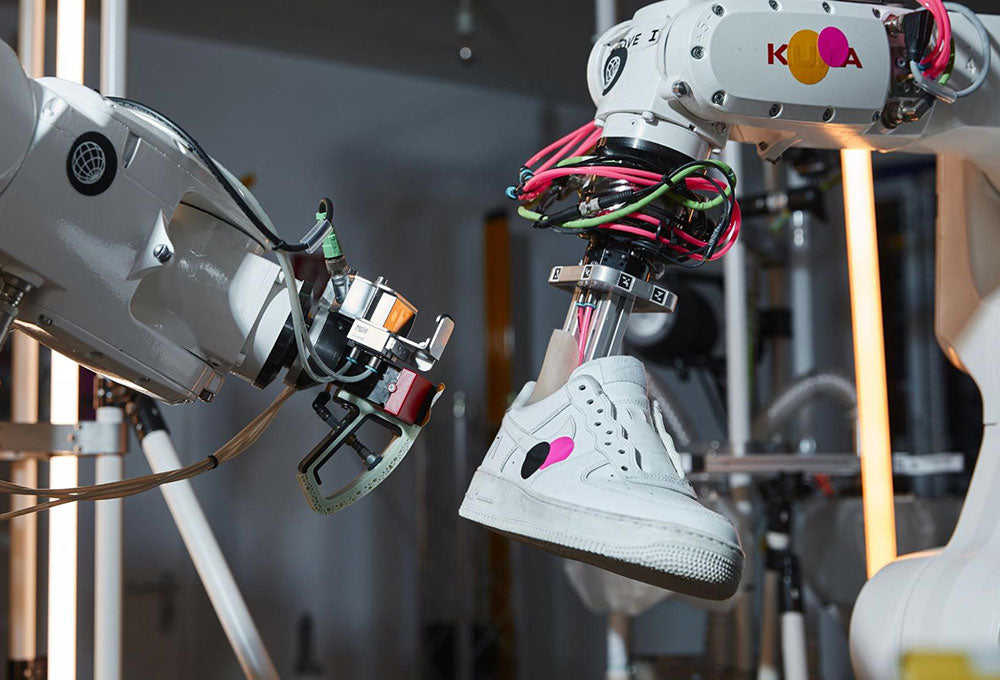

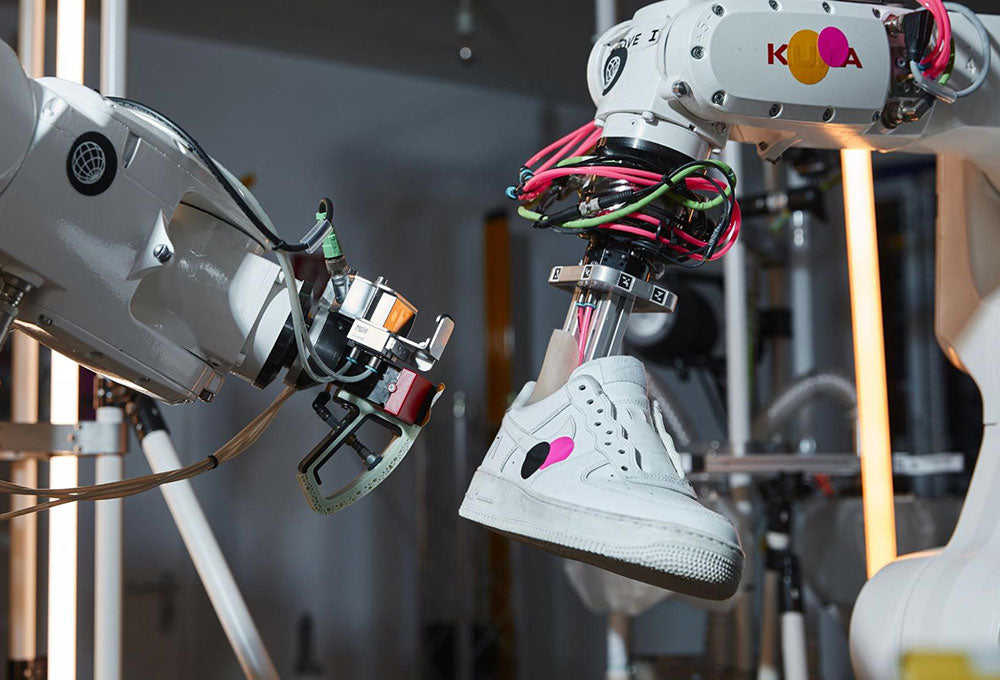

The process begins with design. Traditionally, creating prototypes involved time-consuming manual processes. Now, Nike utilizes advanced robotic systems and 3D printing technologies. Robotic arms precisely layer materials, creating intricate prototypes rapidly.

- Faster iteration: Designers can quickly test different iterations, leading to faster product development cycles.

- Reduced material waste: 3D printing minimizes material waste compared to traditional subtractive manufacturing methods.

- Increased design flexibility: Robotics enables the creation of more complex and customized designs.

- Challenges: The high initial investment in sophisticated 3D printers and robotic arms, and the need for specialized technicians for operation and maintenance, represent significant hurdles.

<h3>Automated Cutting and Sewing</h3>

Once the design is finalized, robotic systems take over the cutting and sewing stages. Laser-guided robotic cutters precisely cut materials, minimizing waste and ensuring consistent accuracy. Advanced sewing robots handle even the most intricate stitching patterns with speed and precision far exceeding human capabilities.

- Increased productivity: Automated cutting and sewing significantly increases the output compared to manual labor.

- Improved consistency: Robotic systems ensure consistent quality across all products, reducing defects.

- Challenges: Adapting robots to handle different materials and varying design complexities requires sophisticated programming and ongoing adjustments.

<h3>Robotic Assembly and Finishing</h3>

The assembly process, once a labor-intensive task, is now largely automated. Robots assemble shoe components—the upper, midsole, and outsole—with remarkable precision. Automated processes for gluing, stitching, and finishing ensure consistent quality control.

- Faster production times: Robotic assembly leads to dramatically faster production cycles.

- Reduced labor costs: While there's an initial investment in robotics, long-term labor costs are significantly reduced.

- Increased precision: Robots consistently achieve high levels of accuracy, minimizing imperfections.

- Challenges: Seamless integration of different robotic systems, along with handling variations in component sizes and shapes, require sophisticated programming and coordination.

<h3>Automated Quality Control and Packaging</h3>

Before shipment, automated quality control systems meticulously inspect finished sneakers. Vision systems identify defects, and robotic arms can even perform minor repairs. Automated packaging processes ensure efficient and consistent product delivery.

- Improved product quality: Automated inspections catch defects that might be missed by human inspectors.

- Faster processing: Automated packaging speeds up the entire shipping process.

- Minimized human error: Automation minimizes human error in both inspection and packaging.

- Challenges: The complexity of integrating various quality control measures into the automated workflow requires careful planning and coordination.

<h2>The Impact of Robotics on Nike's Workforce</h2>

The integration of robotics into Nike's production facilities has significant implications for its workforce. While some traditional manufacturing jobs have been displaced, Nike has invested heavily in reskilling and upskilling initiatives.

<h3>Job Displacement and Reskilling</h3>

Automation inevitably leads to job losses in certain areas. However, Nike actively addresses this by investing in reskilling programs to transition employees into new roles related to robotics and automation.

- Job losses: Roles like manual cutting, sewing, and assembly are being automated.

- Reskilling initiatives: Nike provides training in areas such as robotics engineering, automation maintenance, and data analysis.

- New roles: The shift towards automation creates new job opportunities requiring higher technical skills.

<h3>Increased Productivity and Efficiency</h3>

Robotic systems significantly increase overall productivity, leading to cost savings and quicker response times to market demands.

- Increased productivity: Automation significantly boosts output per unit of time.

- Faster production times: Faster production cycles allow Nike to respond quickly to changing market trends.

- Focus shift: The workforce focus shifts from manual labor to roles requiring higher technical skills and expertise.

<h2>The Future of Robotic Nike Sneaker Production</h2>

The future of robotic Nike sneaker production is bright, promising continued innovation and integration of advanced technologies.

<h3>Advancements in AI and Machine Learning</h3>

AI and machine learning are poised to further revolutionize Nike's production processes.

- Improved decision-making: AI can optimize production schedules, predict potential issues, and improve overall efficiency.

- Predictive maintenance: Machine learning algorithms can predict when robotic systems require maintenance, minimizing downtime.

- More adaptive systems: AI-powered robots will become more adaptable and capable of handling a wider range of tasks.

<h3>Sustainability and Ethical Considerations</h3>

Nike is also focusing on sustainability and ethical considerations in its robotic manufacturing initiatives.

- Environmentally friendly materials: Nike is increasingly utilizing eco-friendly materials in its production.

- Fair labor practices: Nike is committed to ensuring fair labor practices throughout its supply chain, even with automation.

- Addressing economic inequality: Nike is actively addressing concerns about potential economic inequality resulting from automation.

<h2>Conclusion</h2>

The integration of robotics into Nike sneaker production is a complex process with significant implications for efficiency, sustainability, and workforce dynamics. While automation presents challenges in terms of job displacement and initial investment costs, it also unlocks opportunities for increased productivity, higher product quality, and the development of more sustainable manufacturing practices. The future of robotic Nike sneaker production hinges on continuous innovation, thoughtful workforce planning, and a commitment to ethical and sustainable practices. To stay informed about the latest advancements in this fascinating field, continue exploring the complexities of robotic Nike sneaker production and its evolving role in the footwear industry.

Featured Posts

-

Is Blue Origins Downfall Larger Than Katy Perrys Public Image Issues

Apr 22, 2025

Is Blue Origins Downfall Larger Than Katy Perrys Public Image Issues

Apr 22, 2025 -

Will Google Be Broken Up Examining The Growing Risks

Apr 22, 2025

Will Google Be Broken Up Examining The Growing Risks

Apr 22, 2025 -

Tik Tok And Tariffs Analyzing The Just Contact Us Trend Highlighted By Cnn

Apr 22, 2025

Tik Tok And Tariffs Analyzing The Just Contact Us Trend Highlighted By Cnn

Apr 22, 2025 -

Blue Origins Failures A Deeper Dive Than Katy Perrys Mishaps

Apr 22, 2025

Blue Origins Failures A Deeper Dive Than Katy Perrys Mishaps

Apr 22, 2025 -

White House Cocaine Investigation Secret Service Concludes Inquiry

Apr 22, 2025

White House Cocaine Investigation Secret Service Concludes Inquiry

Apr 22, 2025

Latest Posts

-

Ufc 315 Aftermath Shevchenko Considers Zhang Weili Superfight

May 12, 2025

Ufc 315 Aftermath Shevchenko Considers Zhang Weili Superfight

May 12, 2025 -

Manon Fiorots Rise A Contenders Journey

May 12, 2025

Manon Fiorots Rise A Contenders Journey

May 12, 2025 -

Shevchenko Open To Weili Fight Following Ufc 315

May 12, 2025

Shevchenko Open To Weili Fight Following Ufc 315

May 12, 2025 -

Manon Fiorot The Path To A Ufc Championship Bout

May 12, 2025

Manon Fiorot The Path To A Ufc Championship Bout

May 12, 2025 -

Valentina Shevchenko Vs Zhang Weili Superfight Possibilities After Ufc 315

May 12, 2025

Valentina Shevchenko Vs Zhang Weili Superfight Possibilities After Ufc 315

May 12, 2025