Trump Tariffs: The Devastating Blow To Toyota's Bottom Line

Table of Contents

The Impact of Section 232 Tariffs on Toyota's Vehicle Imports

The Section 232 tariffs, imposed on imported steel and aluminum, directly increased the cost of importing vehicles and parts into the US market. This had a cascading effect on Toyota's operations and profitability.

Increased Costs

- Increased import duties: Tariffs added a substantial percentage to the cost of every imported vehicle and component, eating into profit margins. Specific tariffs on steel and aluminum directly impacted the cost of manufacturing vehicles, even those partially assembled in the US.

- Higher production costs: The increased cost of imported materials forced Toyota to either absorb these costs, reducing profitability, or pass them on to consumers, potentially impacting sales.

- Reduced competitiveness: The higher prices made Toyota vehicles less competitive against domestic manufacturers or competitors who sourced materials from countries not subject to the same tariffs. This resulted in a loss of market share.

Reduced Sales and Market Share

The higher prices resulting from Trump tariffs directly impacted consumer demand.

- Decreased consumer demand: Faced with higher prices, many consumers opted for cheaper alternatives, impacting Toyota's sales figures.

- Loss of market share to domestic or non-tariffed competitors: Domestic manufacturers and those sourcing materials from unaffected countries gained a competitive advantage, leading to a measurable decrease in Toyota's market share. This decline is supported by [Insert relevant sales data comparison if available, citing the source].

- Specific sales data comparisons: [Insert specific sales data comparisons for relevant Toyota models before and after the tariff implementation, if available, with proper citation].

Response Strategies

Toyota implemented several strategies to counter the negative effects of the tariffs.

- Price adjustments: Toyota attempted to mitigate the impact by carefully adjusting prices, balancing the need to maintain profitability with the desire to remain competitive.

- Production shifts: The company explored shifting some production to facilities outside the US to reduce reliance on tariff-affected materials.

- Lobbying efforts: Toyota, along with other automakers, engaged in lobbying efforts to push for tariff reductions or exemptions.

- Investment in domestic production: To offset the impact, the company made investments to increase domestic production, aiming to reduce reliance on imports.

The Ripple Effect: Supply Chain Disruptions and Increased Production Costs

The Trump tariffs created a ripple effect throughout Toyota's global supply chain.

Disrupted Supply Chains

The tariffs disrupted established supply chains, leading to delays and increased costs.

- Dependence on specific international suppliers: Toyota, like many automakers, relies on a global network of suppliers. The tariffs disrupted this established network.

- Difficulties in sourcing alternative suppliers: Finding reliable alternative suppliers outside the affected regions proved challenging and time-consuming, leading to production delays.

- Increased logistics costs: The added complexity of navigating the new trade landscape and sourcing parts from alternative locations resulted in significant increases in logistics costs.

Impact on Manufacturing and Employment

The increased costs and supply chain disruptions impacted Toyota's manufacturing plants globally.

- Plant closures: While no plant closures were directly attributed to the tariffs, the challenges caused by the tariffs may have influenced investment decisions regarding future plant expansion or maintenance.

- Reduced production capacity: To absorb the increased costs or adjust to supply chain disruptions, production capacity may have been temporarily reduced in some facilities.

- Job losses (if any): While widespread job losses were not directly linked to the tariffs, the economic pressure may have resulted in slowed hiring or potential workforce adjustments in some areas.

- Changes in investment plans: The tariffs likely led to a reassessment of investment plans, with potential shifts in capital allocation towards mitigating the impact of the tariffs.

Long-Term Consequences: Shifting Global Strategies and Future Investments

The Trump tariffs forced Toyota to re-evaluate its long-term strategies and investment decisions.

Re-evaluation of US Market Investment

The experience significantly impacted Toyota's view of the US market's long-term stability.

- Changes in investment plans: Future investment plans for expansion in the US were likely reconsidered and potentially scaled back in light of the tariff-related uncertainties.

- Reduced expansion projects: Projects that would have increased the company's US footprint were potentially delayed or canceled.

- Reconsidering future US manufacturing facilities: The tariffs likely spurred discussions on the optimal location for future manufacturing facilities, taking into account trade policies and potential risks.

Global Production Diversification

To mitigate future risks, Toyota accelerated its efforts to diversify its global production and supply chains.

- Increased production in other countries: The company likely increased production in regions less susceptible to volatile trade policies.

- Sourcing components from a wider range of locations: Toyota broadened its supplier base, reducing reliance on any single region or country.

- Building more resilient supply chains: The experience underscored the importance of building more diversified and robust supply chains capable of withstanding future trade disruptions.

Conclusion

The Trump tariffs delivered a devastating blow to Toyota's bottom line, resulting in increased costs, reduced sales, supply chain disruptions, and significant long-term strategic shifts. The increased import duties, higher production costs, and reduced competitiveness directly impacted profitability. Supply chain disruptions added further pressure, forcing Toyota to re-evaluate its global production strategy and diversify its supply chains. Understanding the full impact of Trump tariffs on major corporations like Toyota is crucial for informed discussions on future trade policy. Learn more about the ongoing effects of these tariffs and their influence on the global economy, and the long-term impact of protectionist trade policies on multinational corporations.

Featured Posts

-

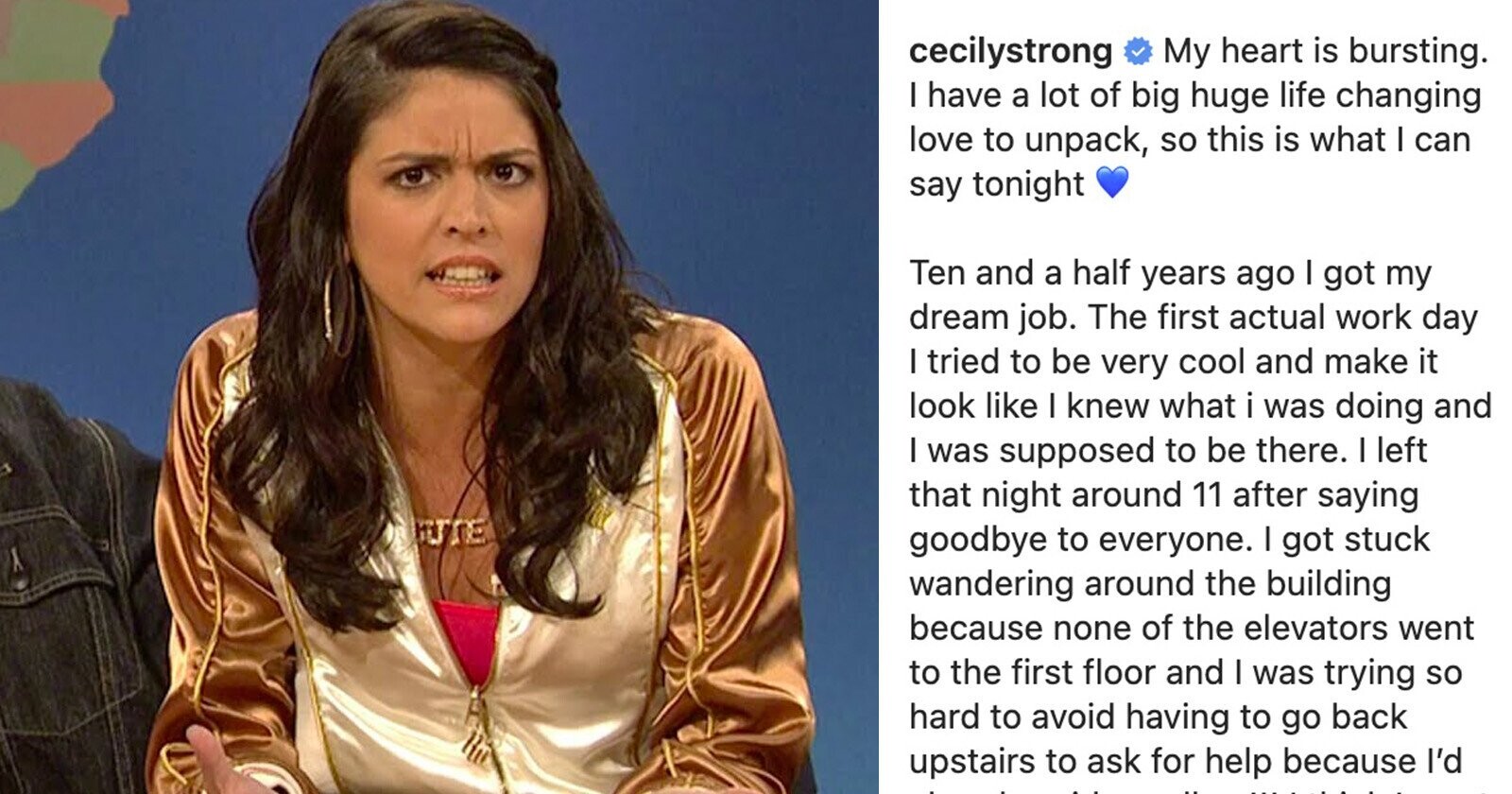

Snl Cold Open Unexpected Appearances By Cecily Strong And Colin Jost

May 12, 2025

Snl Cold Open Unexpected Appearances By Cecily Strong And Colin Jost

May 12, 2025 -

Manon Fiorot Her Fight For A Championship

May 12, 2025

Manon Fiorot Her Fight For A Championship

May 12, 2025 -

The Lyrics Reveal All Jessica Simpsons New Song And The Eric Johnson Cheating Allegations

May 12, 2025

The Lyrics Reveal All Jessica Simpsons New Song And The Eric Johnson Cheating Allegations

May 12, 2025 -

Tres Toros Uruguayos Un Regalo Presidencial Para China

May 12, 2025

Tres Toros Uruguayos Un Regalo Presidencial Para China

May 12, 2025 -

12 1 Tennessee Volunteers Impressive Victory Against Indiana State Sycamores

May 12, 2025

12 1 Tennessee Volunteers Impressive Victory Against Indiana State Sycamores

May 12, 2025