U.S. Firms Implement Cost Reduction Strategies In Response To Tariffs

Table of Contents

Supply Chain Diversification: Sourcing Goods from Alternative Locations

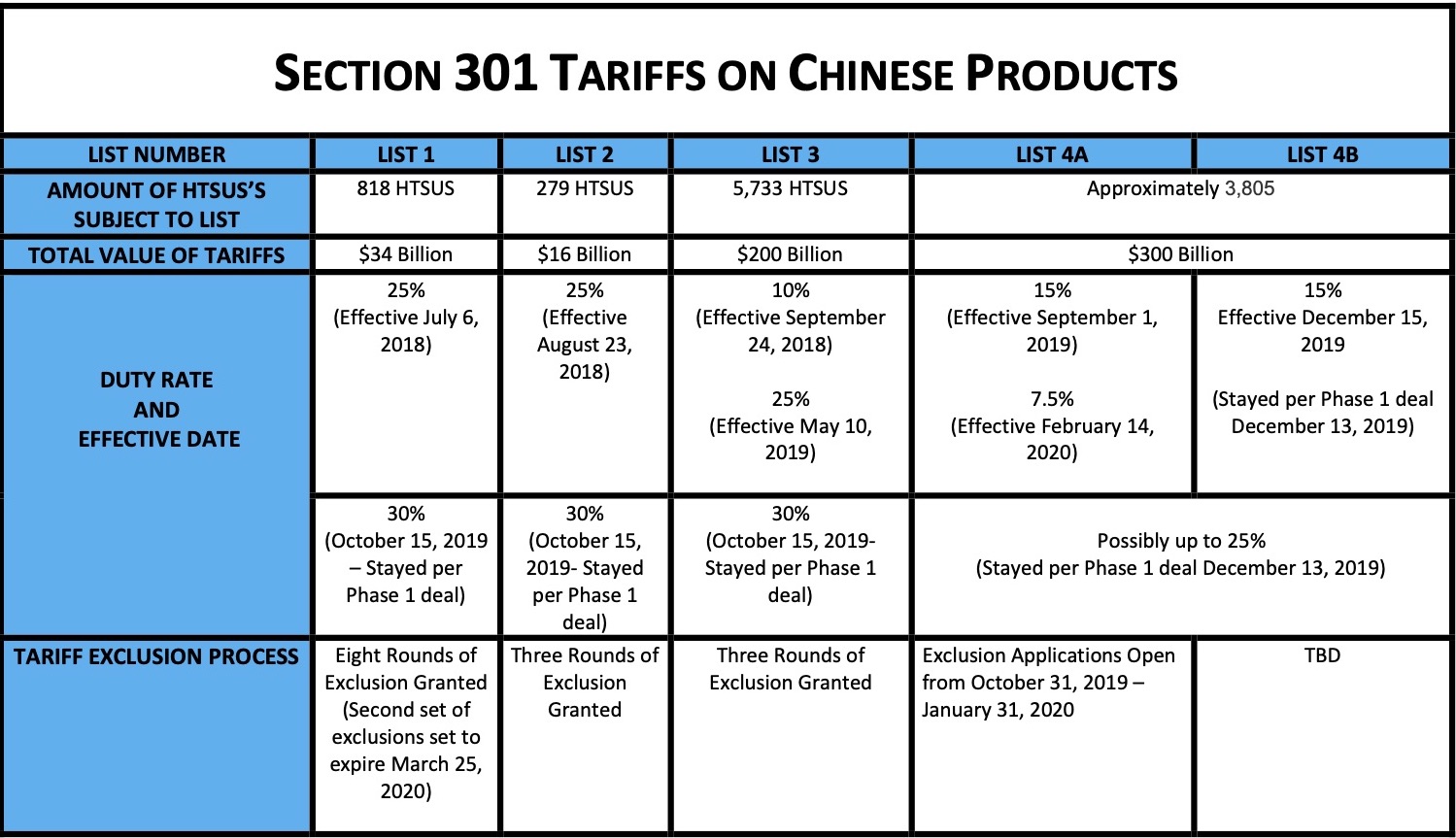

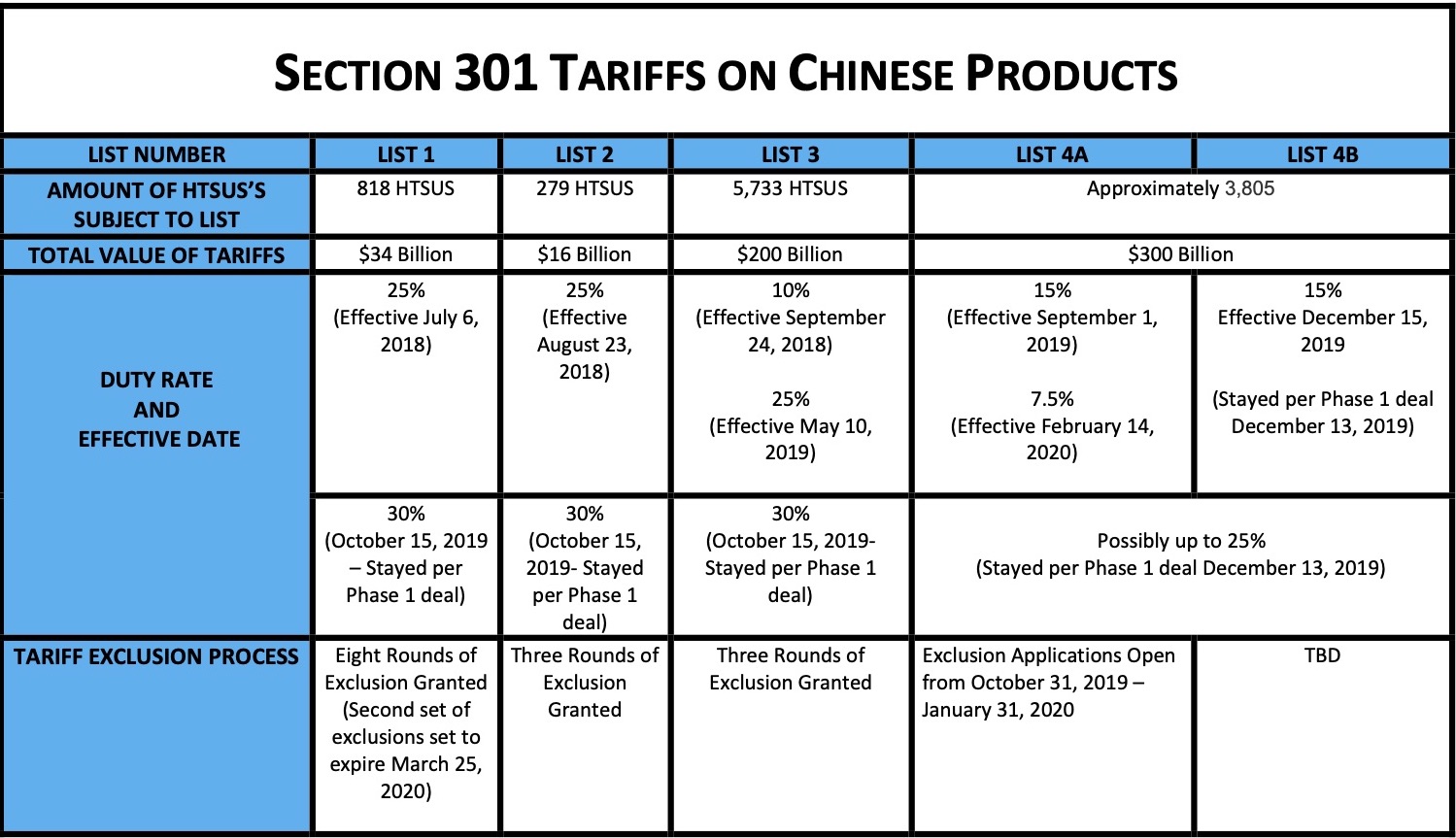

Tariffs have dramatically altered the landscape of global sourcing for U.S. firms. The increased cost of goods imported from tariff-affected countries has forced businesses to explore alternative suppliers in regions unaffected by these trade barriers.

Reducing Reliance on Tariff-Affected Countries

The reliance on single-source suppliers in countries like China has proven vulnerable to tariff volatility. To mitigate this risk, many U.S. businesses are actively diversifying their supply chains.

- Examples of alternative sourcing destinations: Mexico, Vietnam, India, Southeast Asia, and countries in Eastern Europe.

- Challenges associated with supply chain diversification: Increased transportation costs, potential quality control issues, longer lead times, and the complexities of navigating new regulatory environments.

- The shift in sourcing requires careful consideration of logistics and infrastructure. While initially more expensive, long-term benefits include increased resilience to trade disruptions and potentially access to lower labor costs in other regions.

Negotiating Favorable Terms with Existing Suppliers

Even with diversification, maintaining relationships with existing suppliers remains crucial. Negotiating favorable terms with these suppliers can significantly reduce costs.

- Examples of negotiation tactics: Volume discounts, long-term contracts, bundled services, and improved payment terms.

- Potential risks of aggressive negotiation: Damaging supplier relationships, compromising quality, and creating supply chain vulnerabilities.

- Building strong, collaborative relationships with suppliers is paramount. This fosters trust and opens opportunities for mutually beneficial agreements that contribute to long-term cost savings and supply chain stability.

Automation and Technological Advancements: Streamlining Operations for Efficiency

Automation and technological advancements are proving to be vital tools in the fight against tariff-induced cost increases. U.S. firms are investing heavily in these areas to streamline operations and boost efficiency.

Investing in Automation to Reduce Labor Costs

Automation technologies offer a powerful means to reduce labor costs and enhance productivity.

- Examples of automation technologies: Robotics, AI-powered quality control systems, automated warehousing and logistics systems.

- Long-term cost benefits versus initial investment costs: While initial investments can be substantial, long-term cost savings from reduced labor costs, increased efficiency, and reduced waste often outweigh the upfront expense.

- The implementation of automation technologies can impact employment levels. However, this often necessitates workforce reskilling and retraining programs to adapt to the changing demands of a more automated workplace.

Utilizing Technology to Optimize Supply Chain Management

Technology plays a pivotal role in optimizing the entire supply chain. Efficient management minimizes waste and enhances overall operational effectiveness.

- Examples of supply chain management software and technologies: Enterprise Resource Planning (ERP) systems, inventory management software, blockchain technology for improved traceability, and sophisticated data analytics platforms.

- Quantifiable benefits of improved supply chain efficiency: Reduced inventory holding costs, minimized waste, faster delivery times, improved forecasting accuracy, and enhanced responsiveness to market demands.

- Data analytics empowers businesses with the insights needed to make data-driven decisions, leading to improved resource allocation, proactive risk management, and ultimately, lower costs.

Internal Cost-Cutting Measures: Optimizing Existing Processes

Beyond external factors, internal processes present significant opportunities for cost reduction. U.S. firms are focusing on streamlining operations and eliminating waste to bolster their bottom line.

Lean Manufacturing and Waste Reduction

Lean manufacturing principles focus on eliminating waste in all aspects of production. This methodology drives efficiency and reduces costs.

- Specific lean methodologies: Kaizen (continuous improvement), Six Sigma (process improvement), 5S (organization methodology).

- Measurable improvements achieved through waste reduction: Reduced material waste, improved production efficiency, shorter lead times, lower energy consumption, and optimized inventory management.

- Successful implementations often involve employee training and empowerment, leading to a culture of continuous improvement and cost-consciousness.

Renegotiating Contracts and Reducing Overhead

Renegotiating contracts with vendors and optimizing overhead expenses are also crucial cost-cutting strategies.

- Examples of overhead cost reduction strategies: Energy efficiency upgrades, streamlining administrative processes, consolidating office space, and negotiating better rates with utility providers.

- The importance of a comprehensive cost-benefit analysis: Before implementing any cost-cutting measure, a thorough analysis is vital to ensure that the benefits outweigh the potential drawbacks.

- Effective overhead cost reduction strategies can significantly boost profitability and enhance competitiveness, allowing businesses to better absorb the impact of tariffs.

Conclusion: Navigating the Challenges of Tariffs with Effective Cost Reduction Strategies

U.S. businesses facing the challenges posed by tariffs are successfully navigating these obstacles by implementing a diverse range of cost reduction strategies. Supply chain diversification, automation and technology adoption, and internal cost-cutting measures are all playing crucial roles in mitigating the impact of tariffs. The key takeaway is that proactive planning and strategic implementation of these measures are not merely reactive responses, but essential components of a resilient and competitive business model in a volatile global trade environment. To safeguard your business from the ongoing impacts of tariffs, explore and implement these cost reduction strategies. Consider consulting with supply chain experts or management consultants specializing in cost optimization for U.S. firms to develop a tailored approach to mitigating the effects of tariffs on your specific business. Don't wait for the next tariff increase – proactive management of your costs is crucial for long-term success.

Featured Posts

-

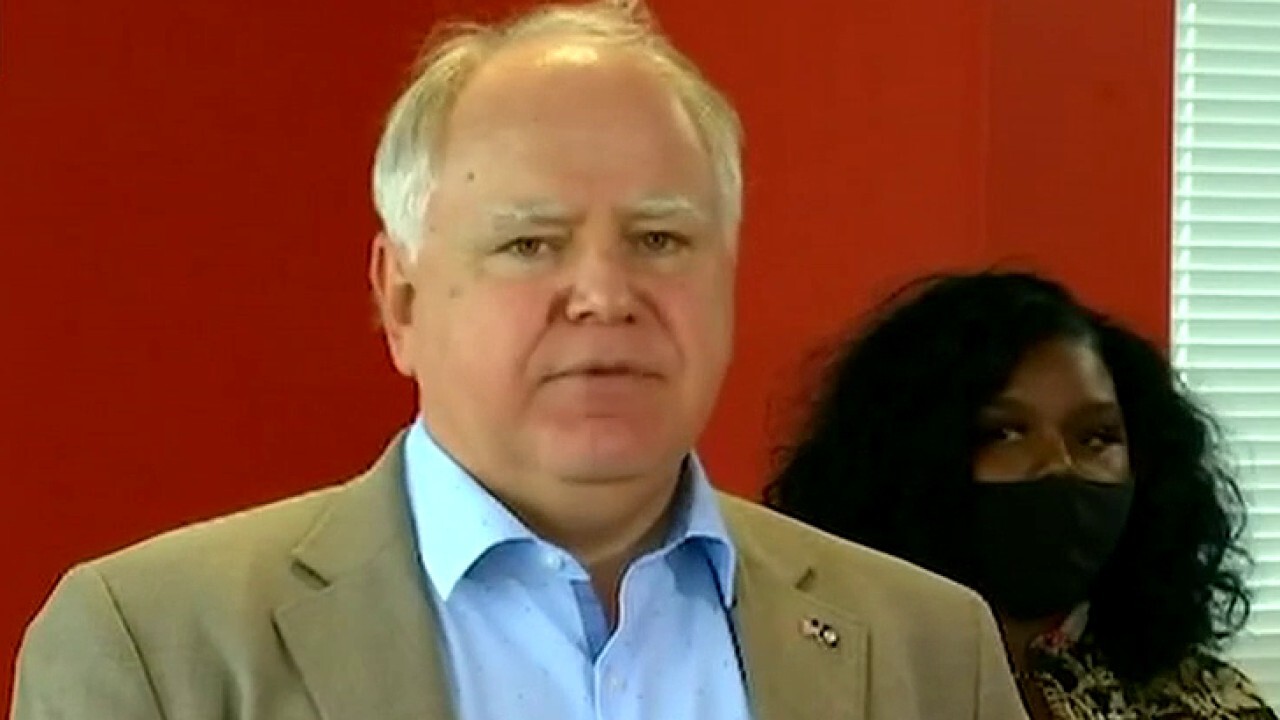

Minnesota Governor Responds To Attorney Generals Transgender Sports Order

Apr 29, 2025

Minnesota Governor Responds To Attorney Generals Transgender Sports Order

Apr 29, 2025 -

Open Ai 2024 Streamlined Voice Assistant Creation For Developers

Apr 29, 2025

Open Ai 2024 Streamlined Voice Assistant Creation For Developers

Apr 29, 2025 -

Trump To Sign Order Creating A National Registry Of Sanctuary Jurisdictions

Apr 29, 2025

Trump To Sign Order Creating A National Registry Of Sanctuary Jurisdictions

Apr 29, 2025 -

How U S Companies Are Managing Costs Under Tariff Uncertainty

Apr 29, 2025

How U S Companies Are Managing Costs Under Tariff Uncertainty

Apr 29, 2025 -

Chargers To Kick Off 2025 Season In Brazil Justin Herberts Role

Apr 29, 2025

Chargers To Kick Off 2025 Season In Brazil Justin Herberts Role

Apr 29, 2025

Latest Posts

-

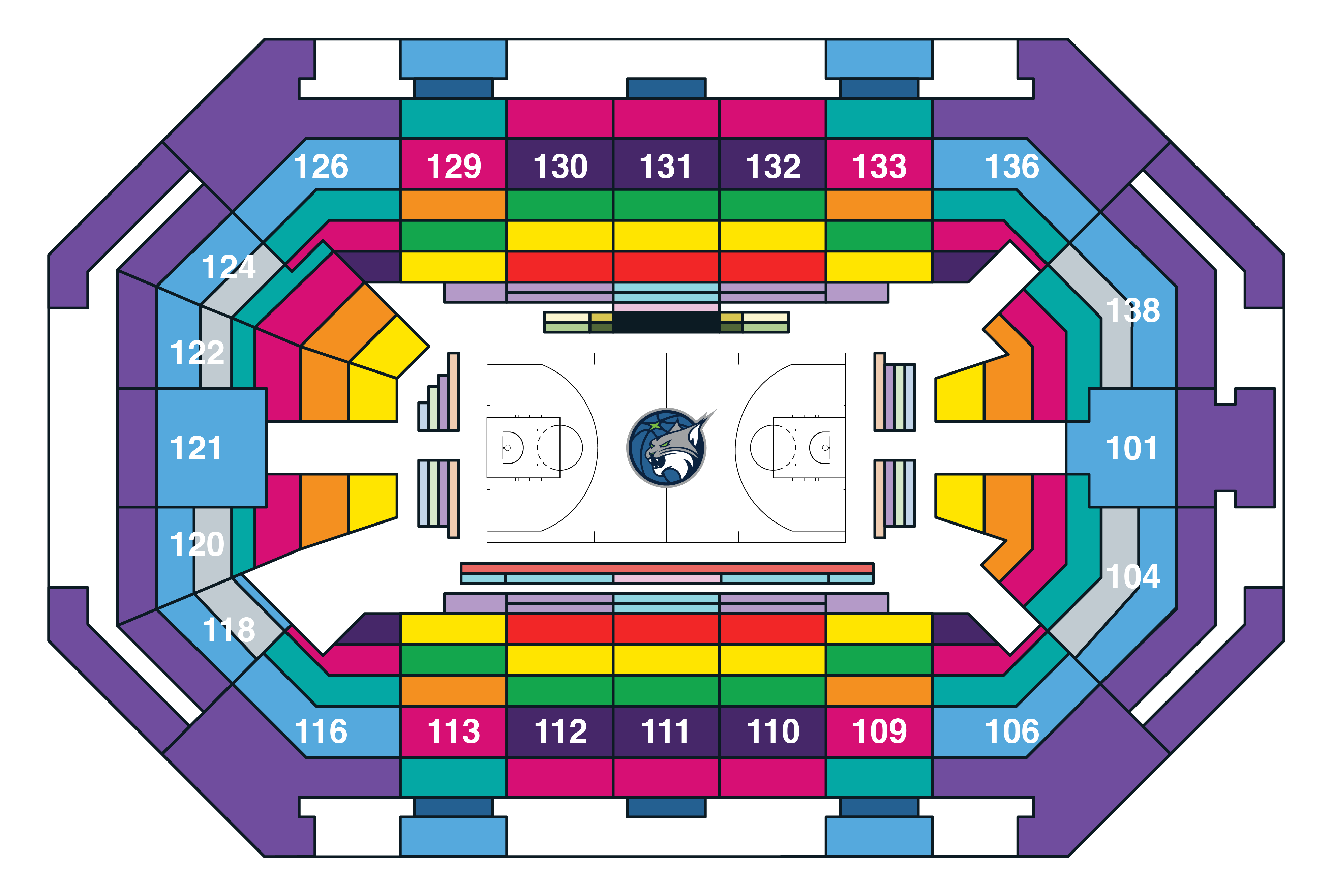

Minnesota Lynx Invite Norfolk States Diamond Johnson To Wnba Training Camp

Apr 29, 2025

Minnesota Lynx Invite Norfolk States Diamond Johnson To Wnba Training Camp

Apr 29, 2025 -

Wnba Bound Diamond Johnsons Journey From Norfolk State To Minnesota Lynx

Apr 29, 2025

Wnba Bound Diamond Johnsons Journey From Norfolk State To Minnesota Lynx

Apr 29, 2025 -

Inter Miami Cf Lionel Messis Matches Schedule Live Stream And Best Betting Sites

Apr 29, 2025

Inter Miami Cf Lionel Messis Matches Schedule Live Stream And Best Betting Sites

Apr 29, 2025 -

Watch Lionel Messi In Mls Inter Miami Game Schedule Live Streaming Options And Betting Predictions

Apr 29, 2025

Watch Lionel Messi In Mls Inter Miami Game Schedule Live Streaming Options And Betting Predictions

Apr 29, 2025 -

Diamond Johnsons Wnba Journey A Norfolk State Stars Minnesota Lynx Opportunity

Apr 29, 2025

Diamond Johnsons Wnba Journey A Norfolk State Stars Minnesota Lynx Opportunity

Apr 29, 2025