UPS Exploring Humanoid Robots With Figure AI Partnership

Table of Contents

Figure AI's Humanoid Robot Technology

Figure AI's humanoid robot is a significant advancement in robotics automation. It boasts a remarkable level of dexterity and intelligence, making it a compelling solution for various logistical challenges. Its capabilities include:

- Advanced dexterity and manipulation skills: The robot can perform intricate tasks requiring fine motor control, such as picking and placing fragile items or sorting packages with precision. This surpasses the capabilities of many traditional automated guided vehicles (AGVs) and other warehouse robotics systems.

- Autonomous navigation and obstacle avoidance: Utilizing advanced sensors and AI, the robot can navigate complex warehouse environments autonomously, avoiding obstacles and adapting to changing conditions. This is crucial for efficient movement within busy logistics hubs.

- Integration potential with existing warehouse systems: Figure AI's robot is designed for seamless integration with existing Warehouse Management Systems (WMS) and other logistics software. This minimizes disruption and maximizes the efficiency of integrating the robot into existing operations.

- Potential for increased efficiency and reduced labor costs: By automating repetitive and labor-intensive tasks, the robot promises to significantly increase efficiency and reduce reliance on human labor for certain operations, leading to potential cost savings.

These capabilities are directly relevant to UPS's needs, addressing challenges in speed, accuracy, and overall throughput in their vast network of warehouses and delivery routes. The robot's design features a robust build, capable of carrying significant weight (specific details to be confirmed by Figure AI), and boasts impressive speed and battery life, enabling prolonged operational periods. Its implementation promises to significantly impact the landscape of warehouse robotics.

UPS's Strategic Goals and the Role of Automation

UPS faces numerous challenges in today's fast-paced logistics environment. The company is constantly striving to optimize its operations and maintain its position as a global leader. Key challenges include:

- E-commerce growth and increased package volume: The explosive growth of e-commerce has led to a massive increase in package volume, putting immense pressure on UPS's existing infrastructure.

- Labor shortages and rising labor costs: Finding and retaining skilled workers is an ongoing challenge, and labor costs continue to rise.

- Demand for faster and more reliable delivery: Consumers expect faster and more reliable delivery, pushing UPS to continuously improve its speed and efficiency.

- Need for improved warehouse efficiency and throughput: Optimizing warehouse operations to handle the increasing volume of packages is crucial for maintaining competitiveness.

Humanoid robots, such as those offered by Figure AI, directly address these challenges. By automating repetitive tasks, these robots can help UPS increase throughput, reduce labor costs, improve accuracy, and ultimately, meet the growing demand for faster delivery. This is a key step in achieving supply chain optimization for the company. The integration represents a significant step toward modernizing e-commerce logistics and enhancing last-mile delivery.

Potential Applications within UPS Operations

The application of humanoid robots within UPS's operations is vast and multifaceted. Potential applications include:

- Package sorting and handling in warehouses: Robots can automate the sorting and handling of packages, improving speed and accuracy while minimizing human error.

- Loading and unloading trucks: Robots can assist with the physically demanding task of loading and unloading packages from trucks, reducing strain on human workers and increasing efficiency.

- Assisting with last-mile delivery: While still in the experimental phase, humanoid robots offer the potential for assisting with last-mile delivery by carrying packages to customer doorsteps, particularly in challenging terrain.

- Inventory management and stock replenishment: Robots could automate inventory checks and restock shelves, optimizing warehouse space and ensuring accurate inventory data.

Each of these applications offers significant benefits, including improved speed, accuracy, safety, and reduced labor costs. This improved automated material handling within warehouse automation contributes to a more efficient and cost-effective logistics operation, particularly in the field of delivery robots.

Challenges and Considerations for Humanoid Robot Integration

While the potential benefits are significant, integrating humanoid robots into real-world logistics settings presents challenges:

- Cost of implementation and maintenance: The initial investment and ongoing maintenance costs associated with humanoid robots can be substantial.

- Integration with existing infrastructure and systems: Seamless integration with existing warehouse systems and infrastructure is crucial for minimizing disruption and maximizing efficiency.

- Safety considerations for human-robot collaboration: Ensuring the safety of human workers working alongside robots is paramount. Robust safety protocols and training programs are essential.

- Regulatory hurdles and legal compliance: Navigating regulatory hurdles and ensuring compliance with relevant laws and regulations is a critical aspect of successful robot integration.

Overcoming these challenges requires careful planning, investment in robust technology, and a proactive approach to safety and regulatory compliance. Addressing these issues through collaborative research and development within the field of robot integration, leveraging advancements in AI in logistics, is crucial for successful robotics deployment.

Conclusion

The partnership between UPS and Figure AI represents a significant step towards a more automated future for the logistics industry. The potential benefits of integrating humanoid robots in logistics are substantial, offering improvements in efficiency, speed, accuracy, and cost reduction. While challenges remain in terms of implementation and cost, the potential rewards make this a significant area of development. The integration of these advanced robotic systems promises to revolutionize package handling, warehouse management, and last-mile delivery. Stay informed about the progress of this and other developments in the field of humanoid robots in logistics, and prepare for a future where automation plays an increasingly important role in package delivery and supply chain management.

Featured Posts

-

Ted Kotcheff Rambo First Bloods Director Dies Aged 94

May 01, 2025

Ted Kotcheff Rambo First Bloods Director Dies Aged 94

May 01, 2025 -

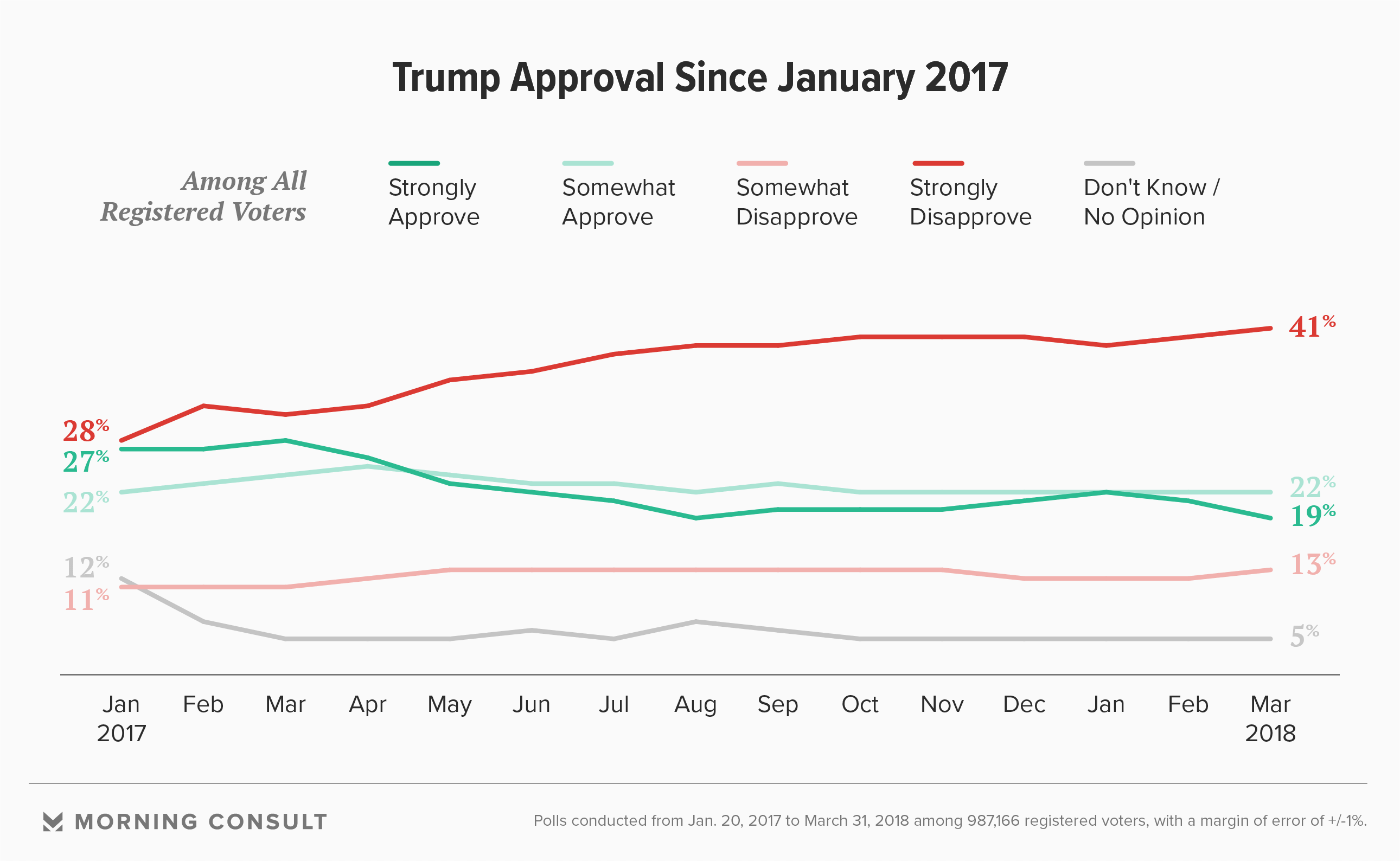

Trumps Approval Rating Plunges A Look At The First 100 Days

May 01, 2025

Trumps Approval Rating Plunges A Look At The First 100 Days

May 01, 2025 -

Channel 4 And Michael Sheen Face Legal Action Over Documentary

May 01, 2025

Channel 4 And Michael Sheen Face Legal Action Over Documentary

May 01, 2025 -

Sources Confirm Nikki Burdines Departure From Wkrn News 2 Morning Show

May 01, 2025

Sources Confirm Nikki Burdines Departure From Wkrn News 2 Morning Show

May 01, 2025 -

Italys Little Tahiti Powdery Sands And Turquoise Waters

May 01, 2025

Italys Little Tahiti Powdery Sands And Turquoise Waters

May 01, 2025

Latest Posts

-

Sedlacek Predvida Jokic I Jovic Na Evrobasketu

May 01, 2025

Sedlacek Predvida Jokic I Jovic Na Evrobasketu

May 01, 2025 -

Matas Buzelis Ir Savo Vardo Turnyro Vilniuje Paslaptis

May 01, 2025

Matas Buzelis Ir Savo Vardo Turnyro Vilniuje Paslaptis

May 01, 2025 -

Evrobasket 2024 Sedlacek O Jokicu I Perspektivama Srbije

May 01, 2025

Evrobasket 2024 Sedlacek O Jokicu I Perspektivama Srbije

May 01, 2025 -

Po Savo Vardo Turnyro Vilniuje Kas Nutiko Matui Buzeliui

May 01, 2025

Po Savo Vardo Turnyro Vilniuje Kas Nutiko Matui Buzeliui

May 01, 2025 -

Sedlacek Analiza Evrobasketa Jokic I Moguci Dolazak Jovica

May 01, 2025

Sedlacek Analiza Evrobasketa Jokic I Moguci Dolazak Jovica

May 01, 2025