Why Nike Shoe Manufacturing Remains A Challenge For Robots

Table of Contents

The Dexterity Challenge: Why Robots Struggle with Fine Motor Skills

The human hand is a marvel of engineering, capable of incredible dexterity and precision. Replicating this in a robot for tasks involved in Nike shoe manufacturing is proving incredibly difficult. This dexterity challenge is a major obstacle to fully automating the process.

Precision and Adaptability

Nike shoe production demands incredibly precise movements. Many tasks require fine motor skills that current robotic technology struggles to match.

- Attaching laces: The intricate weaving and tightening of laces require a level of finesse beyond the capabilities of most robotic grippers.

- Precise stitching of different materials: Stitching various materials like leather, synthetics, and mesh, often with varying thicknesses, necessitates a high degree of dexterity and adaptability that robots currently lack.

- Gluing and applying adhesives: Precise application of adhesives without excess or spillage demands precise control and a "feel" for the material, which is difficult to replicate robotically.

Current robotic grippers and manipulators, while improving, still lack the adaptability and sensitivity of human hands. They struggle to handle the variations in material texture and stiffness, leading to inconsistencies in assembly and potential defects.

Variability in Materials and Designs

Nike constantly innovates, introducing new materials and designs. This variety significantly complicates automation efforts.

- Leather: The varying thickness and texture of leather make consistent handling and processing challenging for robots.

- Synthetics: Different synthetic materials exhibit varying degrees of flexibility and stiffness, requiring different handling techniques.

- Mesh: The delicate nature of mesh materials requires careful handling to prevent tearing or damage during assembly.

The constant evolution of Nike shoe designs and materials necessitates robotic systems capable of adapting to these changes quickly and efficiently. This adaptability is a significant hurdle that requires significant advancements in AI and machine learning.

Material Handling and Supply Chain Integration

Efficient material handling is critical in any manufacturing process, and Nike shoe manufacturing is no exception. Integrating robotic systems into existing production lines and supply chains presents several significant challenges.

Efficient Material Flow

Seamlessly integrating robots into established Nike production lines requires careful consideration of material flow.

- Material feeding: Reliable and consistent feeding of materials to robotic workcells is crucial to maintain production efficiency.

- Material positioning: Precisely positioning materials for robotic manipulation is essential for accurate assembly.

- Waste disposal: Efficiently managing and disposing of waste materials generated during the production process is important for maintaining a clean and organized workspace.

This requires sophisticated sensor systems and AI algorithms to manage the complex flow of materials, adapting to variations in supply and demand.

Dealing with Irregular Shapes and Sizes

Nike shoe components come in various shapes and sizes, making robotic handling challenging.

- Insoles: The complex shapes and varying thicknesses of insoles require adaptable robotic systems for accurate placement.

- Midsole components: Different midsole components, with varying shapes and sizes, need precise handling for proper assembly.

- Outsole units: Handling the irregular shapes of outsole units requires robotic systems with advanced dexterity and manipulation capabilities.

Advanced vision systems and adaptable robotic arms are essential to overcome these challenges. These systems need to be able to quickly identify, locate, and handle components accurately, regardless of their shape or size.

Quality Control and Inspection: Ensuring Perfect Products

Maintaining consistent quality is paramount in Nike shoe manufacturing. Implementing effective quality control using robots presents unique challenges.

Visual and Functional Inspection

Robots struggle to perform comprehensive visual and functional inspections as effectively as humans.

- Detecting stitching defects: Identifying minor stitching defects requires advanced computer vision systems capable of subtle detail recognition.

- Checking for adhesive application: Ensuring proper and consistent adhesive application requires sophisticated sensors and image analysis techniques.

- Assessing overall shoe integrity: Evaluating the overall structural integrity of the finished shoe necessitates a multifaceted inspection process, which is difficult to replicate with current robotic technology.

Advanced computer vision and AI algorithms are being developed to improve inspection accuracy, but achieving human-level precision remains a challenge.

Maintaining Consistency Across Batches

Ensuring consistent quality across different production batches is crucial, and it's a challenge that robots currently struggle to fully address.

- Material variations: Variations in material properties across different batches can affect the assembly process and final product quality.

- Manufacturing process fluctuations: Slight variations in manufacturing parameters can lead to inconsistencies in the final product.

- Environmental factors: Environmental factors, such as temperature and humidity, can also affect quality and need to be controlled.

Data analysis and process optimization are vital to maintaining consistent quality using robots. By monitoring and analyzing data from various stages of the production process, manufacturers can identify and correct deviations from optimal performance, leading to better quality control.

The High Cost of Implementation and Return on Investment

The high cost of implementing robotic systems and the challenges in achieving a quick return on investment are major barriers to widespread adoption in Nike shoe manufacturing.

High Initial Investment Costs

Implementing robotic systems in shoe manufacturing requires a substantial upfront investment.

- Hardware: The cost of robotic arms, grippers, sensors, and other hardware components is significant.

- Software: Developing and integrating the necessary software and control systems adds to the overall cost.

- Integration: Integrating robotic systems into existing production lines requires specialized expertise and significant engineering effort.

The substantial capital expenditure required for robotic automation can be prohibitive for many manufacturers.

Return on Investment (ROI) Challenges

Achieving a satisfactory ROI on robotic automation in shoe manufacturing is challenging.

- Initial costs: The high upfront investment can take considerable time to recoup.

- Maintenance: Robots require regular maintenance and repairs, which adds to the ongoing costs.

- Downtime: Any downtime due to malfunctions or programming issues can significantly impact production efficiency and ROI.

Strategies to improve ROI include focusing on high-volume production lines, optimizing robotic systems for efficiency, and leveraging data analytics to improve overall production efficiency.

Conclusion

Fully automating Nike shoe manufacturing remains a significant challenge due to the dexterity required, complexities in material handling and supply chain integration, difficulties in ensuring consistent quality control, and the high cost of implementation. While current robotic technology has made impressive strides, the intricate and variable nature of Nike shoe production presents hurdles that require further advancements in areas such as AI, sensor technology, and robotic manipulation. However, ongoing research and development continue to push the boundaries of what's possible. Stay informed about the latest advancements in robotic automation to understand the future of shoe production and the ongoing evolution of Nike shoe manufacturing robots.

Featured Posts

-

The Closure Of Anchor Brewing Company A Look Back At Its History

Apr 22, 2025

The Closure Of Anchor Brewing Company A Look Back At Its History

Apr 22, 2025 -

Papal Conclave How The Catholic Church Elects Its Next Leader

Apr 22, 2025

Papal Conclave How The Catholic Church Elects Its Next Leader

Apr 22, 2025 -

New Signal Chat Exposes Hegseth Amidst Pentagon Chaos Claims

Apr 22, 2025

New Signal Chat Exposes Hegseth Amidst Pentagon Chaos Claims

Apr 22, 2025 -

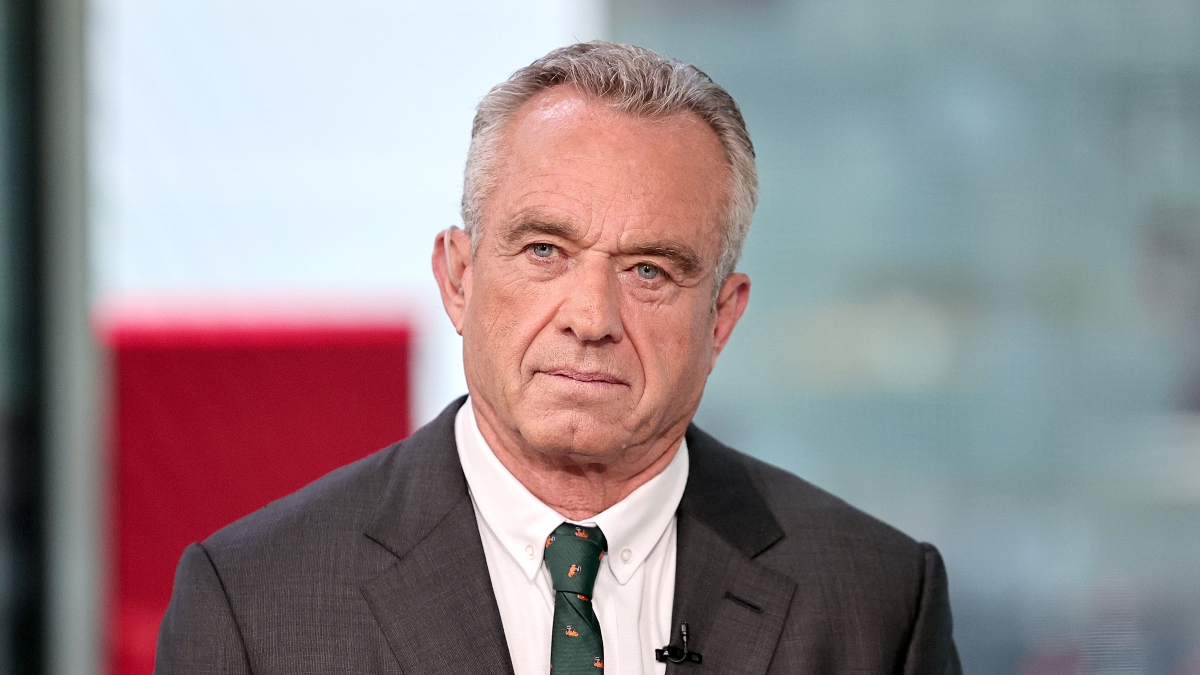

Trumps Unexpected Obamacare Alliance Implications For Rfk Jr S Presidential Bid

Apr 22, 2025

Trumps Unexpected Obamacare Alliance Implications For Rfk Jr S Presidential Bid

Apr 22, 2025 -

Trumps Trade Wars A Case Study In The Erosion Of American Financial Power

Apr 22, 2025

Trumps Trade Wars A Case Study In The Erosion Of American Financial Power

Apr 22, 2025

Latest Posts

-

Could Payton Pritchard Win Nba Sixth Man Of The Year A Celtics Chance

May 12, 2025

Could Payton Pritchard Win Nba Sixth Man Of The Year A Celtics Chance

May 12, 2025 -

Celtics Payton Pritchard Wins Nba Sixth Man Of The Year

May 12, 2025

Celtics Payton Pritchard Wins Nba Sixth Man Of The Year

May 12, 2025 -

Payton Pritchards Nba Sixth Man Of The Year Award Contention

May 12, 2025

Payton Pritchards Nba Sixth Man Of The Year Award Contention

May 12, 2025 -

Payton Pritchard Sixth Man Of The Year A Celtics Unexpected Rise

May 12, 2025

Payton Pritchard Sixth Man Of The Year A Celtics Unexpected Rise

May 12, 2025 -

The Story Behind Payton Pritchards Recent Success A Childhood Perspective

May 12, 2025

The Story Behind Payton Pritchards Recent Success A Childhood Perspective

May 12, 2025