Challenges And Advancements In Automated Visual Inspection Of Lyophilized Vials

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Vials

The automated visual inspection of lyophilized vials presents several complex challenges that impact the accuracy and efficiency of the process. These challenges often require innovative solutions to ensure consistent quality control.

Variations in Lyophilization Processes

Inconsistencies inherent in the lyophilization process itself create significant difficulties for automated visual inspection. These inconsistencies lead to variations in the appearance of the lyophilized cake within the vials, making defect detection extremely challenging.

- Variations in cake appearance: Cracking, collapse, and uneven sublimation of the product are common variations impacting visual inspection.

- Presence of residual moisture: Uneven drying can lead to visible moisture inconsistencies, affecting the accuracy of automated detection.

- Differences in vial clarity: Variations in glass clarity or imperfections in the vial itself can interfere with image analysis and defect identification.

The impact of process parameters such as temperature, pressure, and cycle time on the final visual appearance is considerable. Creating a universal detection algorithm that accounts for all these variations is a significant hurdle in developing robust AVI systems for lyophilized vials.

Difficulties in Defect Detection

Certain defects in lyophilized vials are extremely subtle and difficult to detect using current automated visual inspection technologies. This necessitates ongoing advancements in imaging techniques and algorithms.

- Microscopic particulate matter: Small particles within the lyophilized cake are challenging to identify reliably using standard imaging techniques.

- Subtle cracks or fissures in the lyophilized cake: Minor cracks can compromise product integrity but may be difficult to distinguish from normal variations in cake structure.

- Variations in fill level: Inconsistencies in the fill level of the vials can be subtle but still require accurate detection for quality control purposes.

The limitations of current imaging techniques, including limitations in resolution and challenges in achieving consistent and optimal lighting, further contribute to the difficulties in detecting these subtle defects.

High Throughput Requirements & Cost Considerations

The pharmaceutical industry demands high-throughput inspection to maintain production efficiency. Balancing this requirement with the cost of implementing and maintaining advanced AVI systems poses a significant challenge.

- Balancing speed with accuracy: Faster inspection speeds often compromise the accuracy of defect detection, requiring careful optimization.

- Cost-effectiveness of different technologies: Various AVI technologies exist, each with differing costs and performance characteristics. Selecting the most cost-effective solution that meets quality requirements is vital.

- Integration with existing production lines: Integrating new AVI systems into existing manufacturing lines requires careful planning and can lead to substantial integration costs.

The economic factors influencing the adoption of automated visual inspection systems are crucial considerations for pharmaceutical manufacturers. The trade-off between speed, accuracy, and cost necessitates careful evaluation of different technologies and their suitability for specific applications.

Advancements in Automated Visual Inspection of Lyophilized Vials

Despite the challenges, significant advancements are continuously improving the efficiency and accuracy of automated visual inspection of lyophilized vials. These advancements are paving the way for more reliable and robust quality control in pharmaceutical manufacturing.

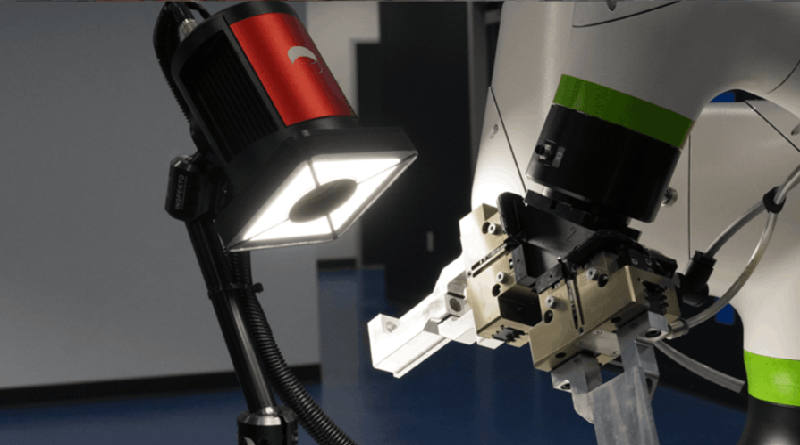

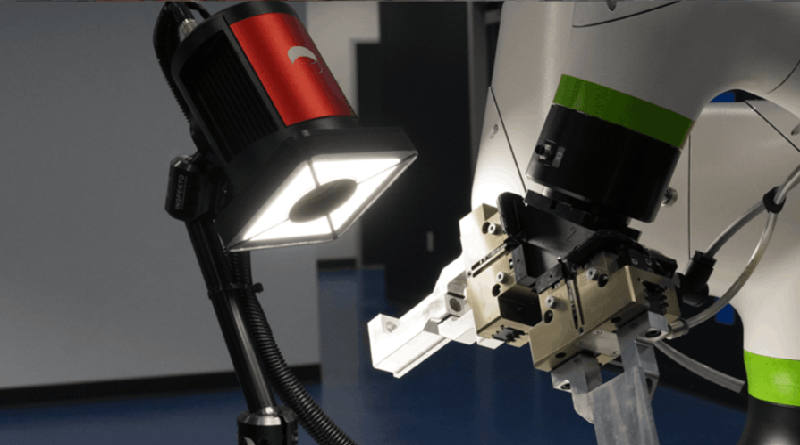

Improved Imaging Technologies

New and improved imaging technologies are offering enhanced sensitivity and resolution capabilities for defect detection, addressing some of the limitations of traditional methods.

- High-resolution cameras: Cameras with increased resolution allow for the detection of smaller and more subtle defects, including microscopic particulate matter and fine cracks.

- Advanced lighting techniques: Multispectral imaging and other advanced lighting techniques enhance contrast and highlight defects that might be otherwise invisible under standard illumination.

- 3D imaging technologies: Three-dimensional imaging provides a more comprehensive view of the lyophilized cake, allowing for the detection of defects that might be obscured in two-dimensional images.

These advanced imaging technologies are directly addressing the challenges outlined earlier, improving the sensitivity and accuracy of defect detection in lyophilized vials.

Advanced Image Processing and AI

The application of artificial intelligence (AI) and machine learning algorithms is revolutionizing automated visual inspection by improving the accuracy and efficiency of defect detection.

- Deep learning algorithms for defect classification: AI algorithms are trained to recognize and classify various types of defects, even subtle ones, with high accuracy.

- Computer vision for pattern recognition: Computer vision techniques enable the system to identify patterns indicative of defects, enhancing the overall reliability of the inspection process.

- Improved algorithms for handling variations in lyophilization processes: Advanced algorithms are being developed to account for the inherent variations in lyophilization processes, reducing false positives and improving the overall accuracy of the inspection.

AI's ability to learn and adapt makes it an invaluable tool in automating the inspection process and improving the accuracy of defect identification, ultimately minimizing human error.

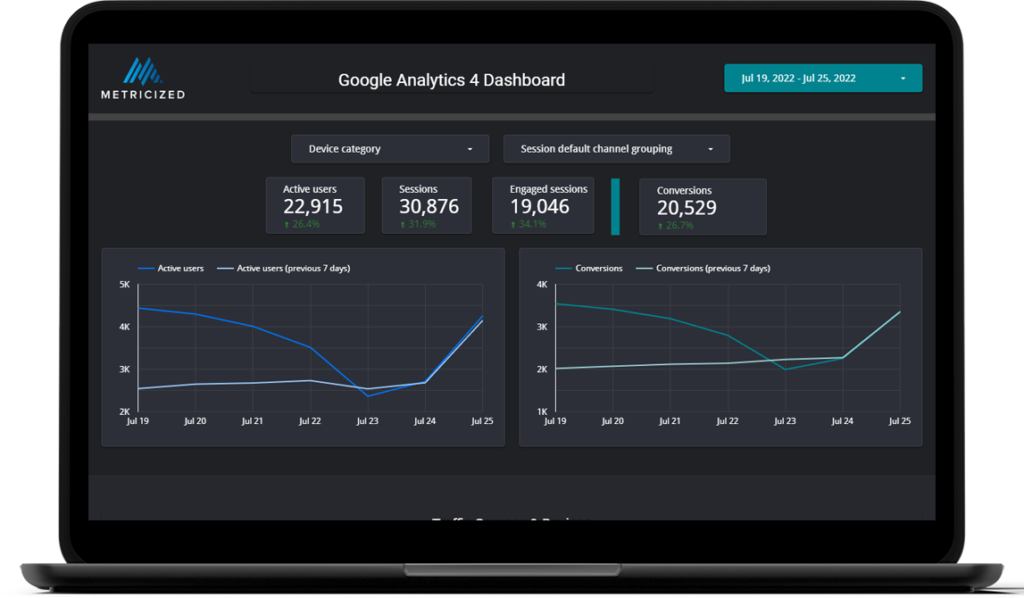

Integration with other Quality Control Systems

Seamless integration with other quality control systems enhances the overall effectiveness of AVI, providing a more holistic view of the lyophilization process and improving traceability.

- Integration with process analytical technology (PAT): Integrating AVI data with PAT data provides a comprehensive understanding of the relationship between process parameters and product quality.

- Data analytics for process optimization: Analyzing data from AVI systems can reveal trends and patterns that can be used to optimize the lyophilization process and reduce defect rates.

- Improved traceability and reporting: Integration with other systems enhances traceability, providing a complete audit trail of the inspection process and improving regulatory compliance.

By integrating AVI data with other quality control data sources, pharmaceutical manufacturers can gain a holistic view of the lyophilization process, leading to improved process control and reduced risks.

Conclusion

Automated visual inspection of lyophilized vials is indispensable for maintaining product quality and ensuring patient safety. While challenges in automated visual inspection of lyophilized vials remain, significant advancements in imaging technologies, AI, and system integration are continuously improving the accuracy, efficiency, and cost-effectiveness of these systems. Embracing these advancements is crucial for ensuring the consistent quality and integrity of lyophilized pharmaceuticals. To learn more about optimizing your automated visual inspection processes and explore the latest advancements in automated visual inspection of lyophilized vials and their impact on pharmaceutical quality control, contact us today to discuss your specific needs.

Featured Posts

-

Ines Reg Critiquee Pour Son Ouverture Dans Dals Natasha St Pier Epargnee

May 12, 2025

Ines Reg Critiquee Pour Son Ouverture Dans Dals Natasha St Pier Epargnee

May 12, 2025 -

New Calvin Klein Campaign Featuring Lily Collins Image 5133598

May 12, 2025

New Calvin Klein Campaign Featuring Lily Collins Image 5133598

May 12, 2025 -

Former Ufc Champion Jose Aldo Targets Featherweight Division

May 12, 2025

Former Ufc Champion Jose Aldo Targets Featherweight Division

May 12, 2025 -

Fun In The Sky Making The Most Of Your Flight

May 12, 2025

Fun In The Sky Making The Most Of Your Flight

May 12, 2025 -

Us China Trade Talks Market Sentiment As The Decisive Factor

May 12, 2025

Us China Trade Talks Market Sentiment As The Decisive Factor

May 12, 2025