Trump's Tariffs: Automakers Struggle With Uncertainty

Table of Contents

Increased Costs and Reduced Profitability

Trump's tariffs directly impacted the bottom line of automakers by significantly increasing the cost of imported parts and materials. The sudden imposition of duties on steel and aluminum, for instance, had a ripple effect throughout the supply chain. This resulted in:

- Higher prices for steel and aluminum: These materials are fundamental to vehicle construction, and the tariff hikes translated to immediate and substantial increases in manufacturing costs.

- Increased costs of imported engines and components: Many automakers rely on globally sourced engines, transmissions, and other crucial components. Tariffs on these imports drastically increased their production expenses.

- Reduced profit margins due to increased production costs: The rising costs of raw materials and components squeezed profit margins, forcing automakers to either absorb the losses or pass them on to consumers.

- Examples of specific automakers affected and the extent of their losses: Companies like Ford and General Motors publicly reported significant cost increases due to the tariffs, impacting their profitability and forcing strategic adjustments. The precise extent of losses varied depending on each automaker's reliance on imported parts and their ability to negotiate with suppliers.

This surge in production costs inevitably influenced vehicle pricing. Automakers faced a difficult choice: absorb the increased costs and reduce profit margins, or pass them on to consumers, potentially impacting sales volume due to decreased consumer demand in a price-sensitive market.

Supply Chain Disruptions and Restructuring

Maintaining a stable and efficient supply chain became a Herculean task for automakers under the weight of Trump's tariffs. The sudden changes in import costs and the resulting uncertainty forced companies to completely rethink their sourcing strategies. The challenges included:

- Difficulties in sourcing parts from affected countries: The tariffs created significant hurdles for automakers sourcing parts from countries targeted by the new duties.

- The need for automakers to diversify their sourcing strategies: To mitigate risks associated with relying on single suppliers or regions, automakers had to diversify their supply chains, sourcing parts from a wider range of countries.

- Increased logistical costs associated with sourcing from alternative suppliers: Shifting sourcing to new suppliers often entailed increased transportation costs and logistical complexities.

- Examples of companies shifting production or sourcing to mitigate the impact: Some automakers responded by shifting production to countries outside the scope of the tariffs, while others actively sought alternative suppliers within the US or other unaffected regions.

These disruptions highlighted the fragility of global supply chains in the face of protectionist trade policies and led to long-term reevaluations of sourcing strategies within the auto industry.

Political and Economic Uncertainty

The unpredictable nature of Trump's tariff policies created significant uncertainty, chilling long-term investment decisions for automakers. This unpredictability led to:

- Hesitation to invest in new plants or technologies due to uncertainty: The fear of further tariff hikes or changes in trade policy made automakers hesitant to commit to large-scale investments.

- Challenges in forecasting future production costs and pricing strategies: The fluctuating cost of imported materials made it extremely difficult to accurately forecast production costs and develop effective pricing strategies.

- Potential for further trade disputes impacting the auto industry: The imposition of tariffs on one set of goods often escalated into further trade disputes, creating a climate of ongoing uncertainty.

- Impact on job security and potential job losses within the sector: The economic instability caused by the tariffs threatened job security and in some cases led to job losses within the auto industry.

The broader economic impact extended beyond the automotive sector, affecting related industries and creating a climate of economic uncertainty that hampered overall growth.

Adaptation Strategies Employed by Automakers

Faced with these unprecedented challenges, automakers implemented various strategies to navigate the turbulent waters of Trump's tariffs. These included:

- Relocation of production facilities: Some automakers relocated parts of their manufacturing operations to countries outside the scope of the tariffs to reduce import costs.

- Increased domestic sourcing of parts and materials: Many automakers prioritized sourcing parts and materials from domestic suppliers to minimize the impact of tariffs.

- Negotiation with suppliers for better pricing: Automakers engaged in intensive negotiations with their suppliers to secure better pricing and more favorable contracts.

- Lobbying efforts to influence trade policy: Industry groups and individual automakers engaged in lobbying efforts to influence government trade policies.

- Implementation of cost-cutting measures to offset increased costs: Automakers implemented various cost-cutting measures to offset the increased costs imposed by the tariffs.

The effectiveness of these strategies varied greatly depending on factors such as the automaker's size, global reach, and existing supply chain infrastructure. The long-term sustainability of these strategies remains a subject of ongoing analysis and debate within the industry.

Conclusion: Understanding the Lasting Impact of Trump's Tariffs on Automakers

Trump's tariffs presented automakers with a trifecta of challenges: increased costs, supply chain disruptions, and profound economic uncertainty. In response, automakers employed a range of adaptation strategies, including relocation of production, domestic sourcing, and intense negotiations with suppliers. While some strategies proved effective in mitigating the immediate impact, the long-term implications of these tariffs and the vulnerabilities they exposed within global supply chains remain significant. The impact of Trump's tariffs on the auto industry serves as a cautionary tale about the far-reaching consequences of protectionist trade policies. Understanding these challenges is crucial for navigating future trade uncertainties. Learn more about the long-term effects of Trump's tariffs and their ongoing impact on the global automotive landscape. Stay informed about evolving trade policies and their effects on the industry.

Featured Posts

-

Middle Managers Bridging The Gap Between Leadership And Employees

May 03, 2025

Middle Managers Bridging The Gap Between Leadership And Employees

May 03, 2025 -

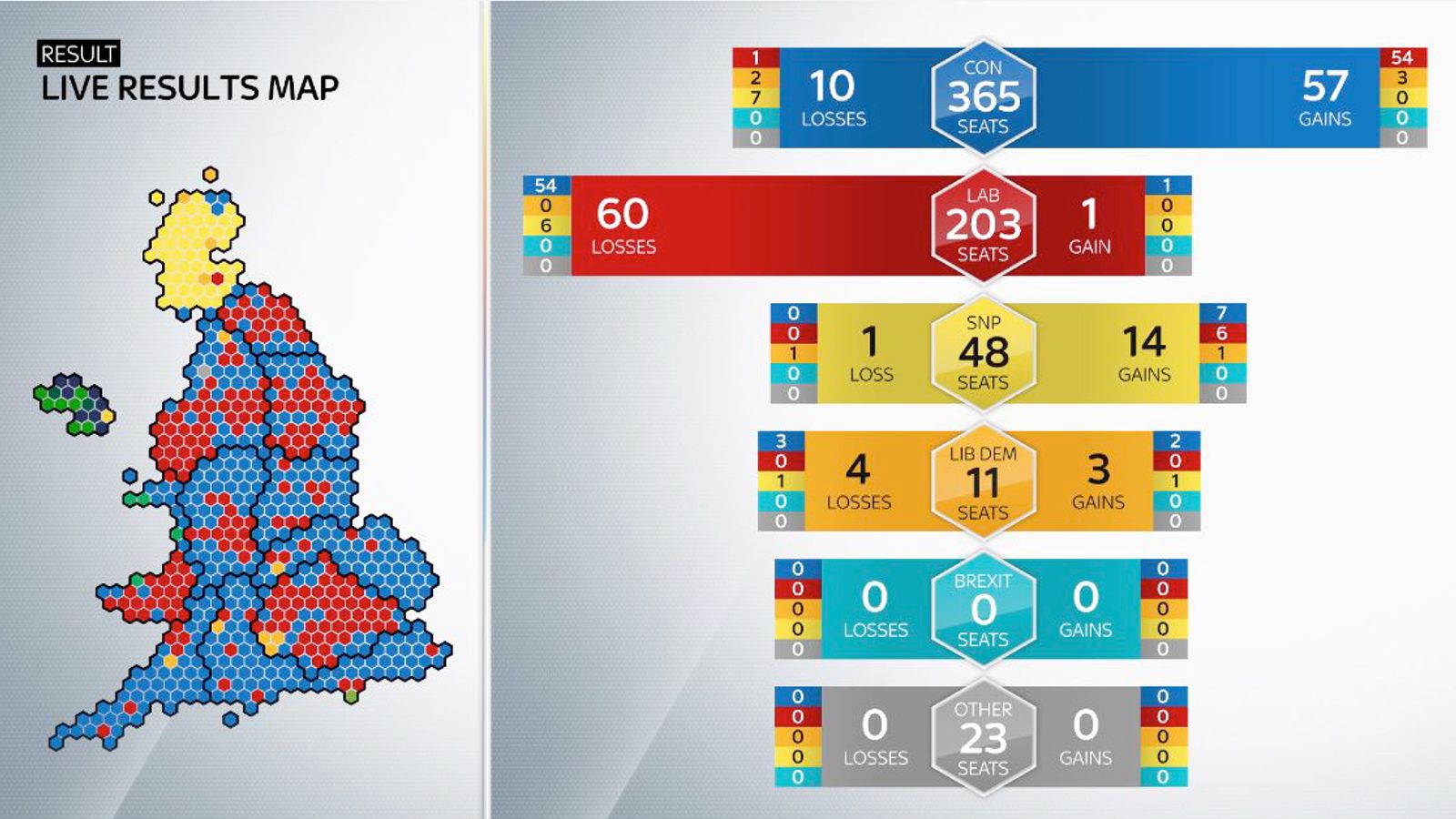

Local Elections 2024 The Reform Partys Electoral Challenge In The Uk

May 03, 2025

Local Elections 2024 The Reform Partys Electoral Challenge In The Uk

May 03, 2025 -

Analysis Fortnite Refunds And Their Impact On Cosmetic Sales

May 03, 2025

Analysis Fortnite Refunds And Their Impact On Cosmetic Sales

May 03, 2025 -

School Desegregation Order Rescinded Expect Similar Cases To Follow

May 03, 2025

School Desegregation Order Rescinded Expect Similar Cases To Follow

May 03, 2025 -

Guide Des Concerts Et Spectacles A La Seine Musicale 2025 2026

May 03, 2025

Guide Des Concerts Et Spectacles A La Seine Musicale 2025 2026

May 03, 2025

Latest Posts

-

Doctor Who Russell T Davies Hints At Seasons 4 And 5

May 03, 2025

Doctor Who Russell T Davies Hints At Seasons 4 And 5

May 03, 2025 -

Doctor Who Cancellation Fears Rise After Showrunners Pause Reveal

May 03, 2025

Doctor Who Cancellation Fears Rise After Showrunners Pause Reveal

May 03, 2025 -

Doctor Whos Future In Jeopardy A Production Hiatus On The Horizon

May 03, 2025

Doctor Whos Future In Jeopardy A Production Hiatus On The Horizon

May 03, 2025 -

Woke Criticism Validates Doctor Whos Direction Says Star

May 03, 2025

Woke Criticism Validates Doctor Whos Direction Says Star

May 03, 2025 -

Doctor Who Future Uncertain Showrunner Hints At Potential Pause

May 03, 2025

Doctor Who Future Uncertain Showrunner Hints At Potential Pause

May 03, 2025