Electric Vehicle Dependence On Dysprosium: Risks And Mitigation Strategies

Table of Contents

H2: The Crucial Role of Dysprosium in Electric Vehicle Motors

Electric vehicles rely heavily on powerful and efficient motors, and these motors depend significantly on high-performance magnets. The heart of many EV motors is the neodymium magnet, a type of rare earth magnet known for its exceptional magnetic properties.

H3: Neodymium Magnets and Their Dependence on Dysprosium

Neodymium magnets are incredibly strong and capable of withstanding high temperatures and significant magnetic fields. However, to achieve their optimal performance, particularly their resistance to demagnetization (high coercivity), a crucial additive is dysprosium. This rare earth element significantly enhances the magnet's ability to retain its magnetism under demanding operating conditions.

- Dysprosium's contribution to higher operating temperatures: Allows for higher power density and efficiency in EV motors, leading to improved range and performance.

- The impact of dysprosium content on the efficiency and longevity of EV motors: Higher dysprosium content translates to longer-lasting magnets and more efficient motors.

- Comparison with alternative magnet materials and their limitations: While alternative magnet materials exist, they often lack the same high-performance characteristics as dysprosium-enhanced neodymium magnets, leading to compromises in motor efficiency and lifespan. This makes dysprosium currently irreplaceable in many high-performance applications.

H2: Geopolitical Risks and Supply Chain Vulnerabilities

The global supply of dysprosium is highly concentrated, creating significant geopolitical risks and supply chain vulnerabilities.

H3: Concentration of Dysprosium Production

China currently dominates the global dysprosium market, controlling a substantial portion of mining, processing, and refining. This concentration creates a significant point of vulnerability for the EV industry. Relying heavily on a single nation for such a critical component exposes the industry to potential disruptions.

H3: Price Volatility and Supply Disruptions

Geopolitical instability, trade wars, and environmental regulations in dysprosium-producing regions can lead to unpredictable price swings and supply disruptions. This volatility creates uncertainty for EV manufacturers and impacts the cost of EV production and consumer affordability.

- Examples of past and potential future supply chain disruptions: Past instances of export restrictions and price hikes demonstrate the vulnerability of relying on a concentrated supply source.

- The impact of price volatility on the cost of EV production and consumer affordability: Fluctuations in dysprosium prices directly impact the manufacturing cost of EVs, potentially affecting their market competitiveness.

- Discussion of potential political risks and trade restrictions: Geopolitical tensions and trade disputes can easily disrupt the flow of dysprosium, impacting EV production.

H2: Environmental Concerns Associated with Dysprosium Mining and Processing

The extraction and processing of dysprosium come with significant environmental consequences.

H3: Environmental Impact of Mining

Dysprosium mining, like many rare earth element mining operations, often involves open-pit mining, leading to habitat destruction, water pollution from acid mine drainage, and soil erosion.

H3: Processing and Refining Challenges

The processing and refining of dysprosium are energy-intensive and involve the use of hazardous chemicals, creating further environmental risks.

- Specific environmental impacts of dysprosium mining and processing: These include air and water pollution, biodiversity loss, and greenhouse gas emissions.

- The role of sustainable mining practices in mitigating environmental damage: Implementing stricter environmental regulations and promoting sustainable mining practices can minimize the environmental footprint.

- Discussion of the carbon footprint of dysprosium production: The overall carbon footprint of dysprosium production needs to be carefully considered and reduced.

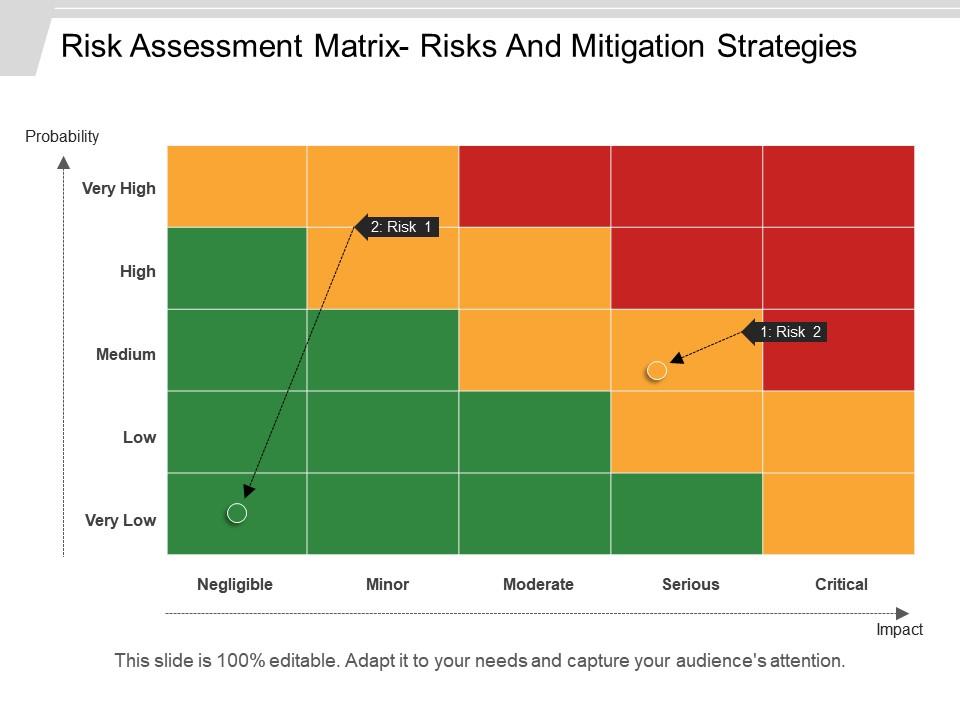

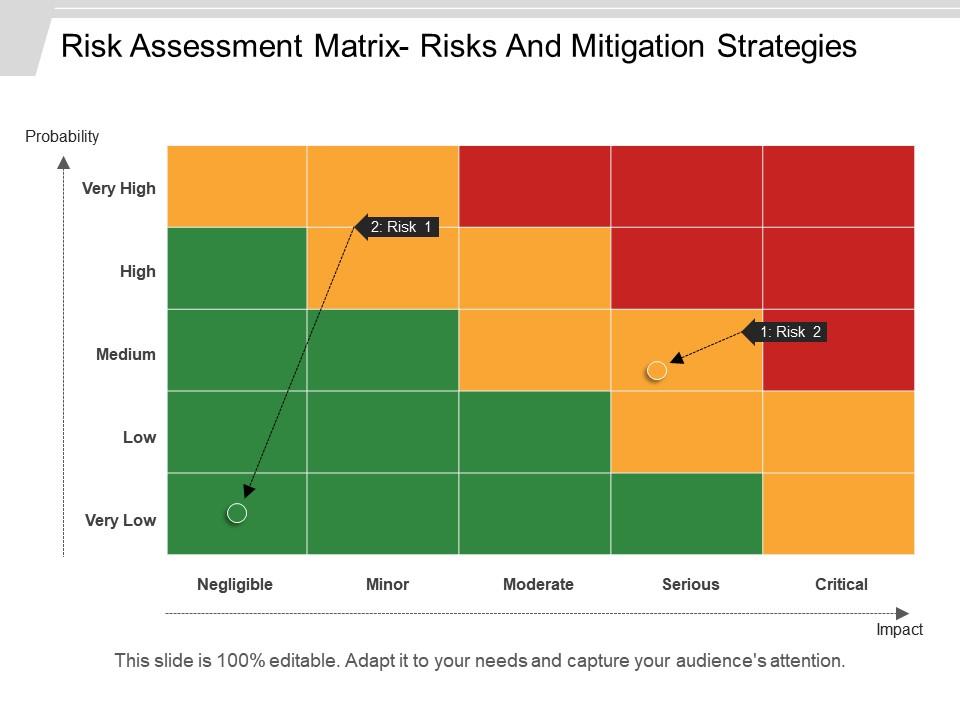

H2: Mitigation Strategies for Reducing Dysprosium Dependence

Addressing the risks associated with dysprosium dependence requires a multi-pronged approach focusing on several key strategies.

H3: Developing Alternative Magnet Materials

Intensive research is underway to develop alternative magnet materials that require less or no dysprosium. These include exploring different rare earth compositions and investigating entirely new magnet materials.

H3: Improving Magnet Design and Efficiency

Optimizing magnet design and improving the efficiency of electric motors can reduce the amount of dysprosium needed to achieve the desired performance. This involves advancements in motor technology and magnet architecture.

H3: Recycling and Urban Mining

Recycling dysprosium from end-of-life EVs is crucial. Developing efficient and cost-effective recycling technologies, along with exploring urban mining techniques to recover dysprosium from existing waste streams, can significantly reduce reliance on primary mining.

H3: Diversification of Supply Chains

Diversifying the global supply chain for dysprosium is paramount. This includes encouraging mining and processing in multiple countries to reduce dependence on any single source.

- Examples of alternative magnet materials under development: Researchers are exploring various alloys and composite materials.

- Strategies for improving magnet design and motor efficiency: Advanced simulations and material science are key to optimizing magnet design.

- Technological advancements in recycling and urban mining of dysprosium: Innovations in hydrometallurgy and other separation techniques are improving recovery rates.

- Policy recommendations for promoting supply chain diversification: Government incentives and international collaborations are crucial for fostering diversification.

3. Conclusion

The reliance of electric vehicles on dysprosium presents significant geopolitical, environmental, and economic risks. The concentrated nature of dysprosium production, its price volatility, and the environmental impact of its mining and processing necessitate urgent action. Mitigating these risks requires a concerted effort involving the development of alternative magnet materials, improvements in magnet design and motor efficiency, increased recycling efforts, and diversification of supply chains. By embracing these mitigation strategies, the electric vehicle industry can ensure its sustainable growth and contribute to a cleaner transportation future. We must actively pursue solutions to reduce dysprosium dependence and foster the development of truly sustainable electric vehicle technology. Learn more about mitigating dysprosium risks and support research into reducing dysprosium dependence in electric vehicles.

Featured Posts

-

Black Hawk Helicopter Crash Pilot Ignored Instructors Warnings

Apr 29, 2025

Black Hawk Helicopter Crash Pilot Ignored Instructors Warnings

Apr 29, 2025 -

Watch Untucked Ru Pauls Drag Race Season 17 Episode 8 Free Streaming Guide

Apr 29, 2025

Watch Untucked Ru Pauls Drag Race Season 17 Episode 8 Free Streaming Guide

Apr 29, 2025 -

Pw Cs Controversial Downsizing Exit Strategy From Over A Dozen Countries Explained

Apr 29, 2025

Pw Cs Controversial Downsizing Exit Strategy From Over A Dozen Countries Explained

Apr 29, 2025 -

Urgent Security Threat Forces Cancellation Of German And Austrian Syria Trip

Apr 29, 2025

Urgent Security Threat Forces Cancellation Of German And Austrian Syria Trip

Apr 29, 2025 -

Is The U S Dollar Headed For Its Worst 100 Days Under A New Presidency Since Nixon

Apr 29, 2025

Is The U S Dollar Headed For Its Worst 100 Days Under A New Presidency Since Nixon

Apr 29, 2025