Robotic Limitations In Nike Sneaker Manufacturing: A Deep Dive

Table of Contents

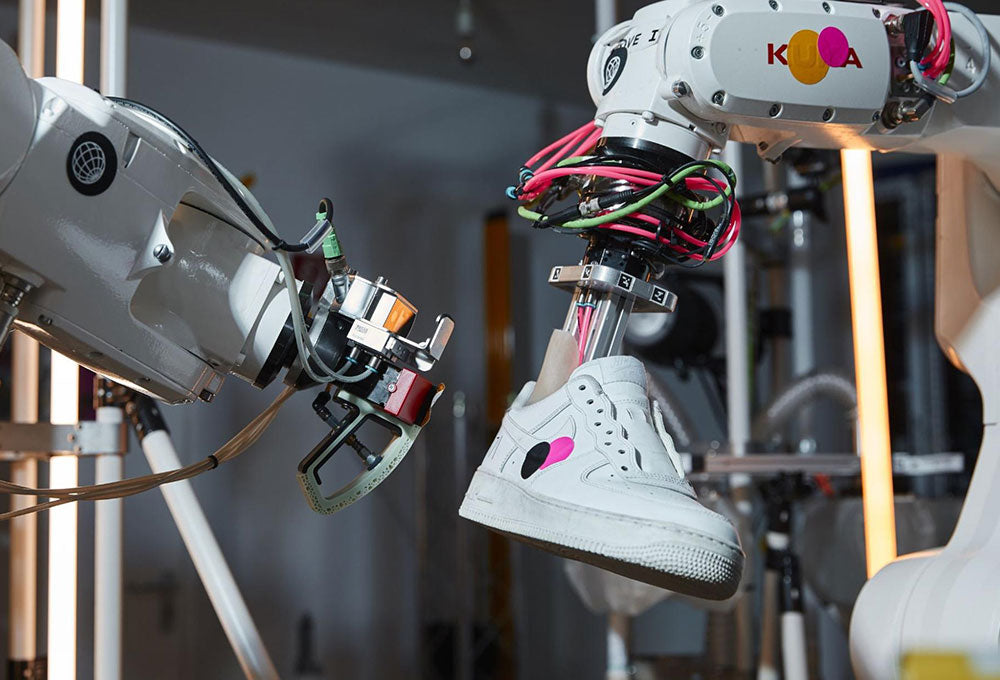

Dexterity and Precision Challenges in Complex Assembly

Sneaker manufacturing is a surprisingly intricate process. Creating a single shoe involves numerous delicate steps requiring fine motor skills and adaptability—qualities that currently pose significant challenges for robots. The precision needed for tasks like stitching thin fabrics, precisely placing adhesives, and ensuring consistent pressure throughout the process is difficult for even the most advanced robotic arms to replicate.

- Difficulties in handling delicate materials: The thin, flexible materials used in many Nike sneakers often prove too delicate for robotic manipulation. The risk of tearing or damaging the material during automated assembly is significantly higher than with human workers.

- Challenges with varying shoe sizes and styles: Robots struggle with the adaptability required to handle different shoe sizes and styles efficiently. Reprogramming for each variation is time-consuming and costly.

- Limitations in dealing with inconsistencies in material quality or shape: Robots require consistent inputs. Variations in material quality or shape, however small, can disrupt the automated process and lead to errors.

- High cost of developing robots with the necessary dexterity: Creating robots with the dexterity and precision of a skilled human worker requires significant investment in research and development, pushing up the initial cost of implementing robotic solutions.

Cost and Return on Investment (ROI) Concerns

The significant upfront investment required for robotic systems in sneaker manufacturing is a major obstacle. This includes not only the purchase price of the robots themselves but also installation, programming, and ongoing maintenance.

- Comparison of robotic automation costs versus human labor costs: While automation promises long-term cost savings, the initial outlay can be substantial, potentially exceeding the cost of employing human workers, at least in the short term.

- Lengthy payback period for some robotic implementations: The return on investment (ROI) for robotic systems in sneaker manufacturing can be lengthy, depending on factors like production volume and the complexity of the tasks being automated.

- Specialized technicians and ongoing maintenance expenses: Robotic systems require specialized technicians for programming, maintenance, and repair, adding to the overall operational costs.

- Potential for job displacement and social implications: The introduction of robots into the manufacturing process raises concerns about job displacement and the social impact on workers.

Adaptability to Design Changes and Customization

The fast-paced nature of the fashion industry, with its frequent design updates, presents another major hurdle for robotic automation in sneaker production.

- Reprogramming robots for new designs involves time and expense: Every design change requires reprogramming the robots, a time-consuming and expensive process that reduces the overall efficiency of automation.

- Limited ability of current robots to handle highly customized or personalized orders: The trend towards customized sneakers poses a further challenge, as current robotic systems struggle to handle the variety and complexity of personalized orders efficiently.

- The need for flexible and easily reprogrammable robotic solutions: The future of robotic automation in sneaker manufacturing depends on the development of more flexible and adaptable robotic systems that can be easily reprogrammed to accommodate new designs and customization options.

The Role of Human Labor Remains Crucial

Despite advancements in robotics, human labor continues to play a vital role in Nike sneaker manufacturing. Many tasks still require human expertise and adaptability.

- Quality control and inspection of finished products: Human inspectors are essential for identifying defects and ensuring the quality of the finished products, a task that current robotic systems struggle to perform with the same level of accuracy.

- Troubleshooting and repair of robotic systems: Robots, like any complex machinery, can malfunction. Human technicians are crucial for troubleshooting and repairing robotic systems to minimize downtime.

- Handling unexpected situations or production errors: Robots are programmed for specific tasks and struggle to adapt to unexpected situations or production errors. Human workers are needed to handle these unexpected events.

- The value of skilled craftsmanship in sneaker production: The skill and craftsmanship of human workers remain invaluable in certain aspects of sneaker production, particularly in tasks requiring fine motor skills, creativity, and problem-solving.

Technological Advancements and Future Potential

Despite the current limitations, ongoing technological advancements hold the promise of overcoming some of these challenges.

- Advancements in artificial intelligence (AI) and machine learning: AI and machine learning can potentially improve the dexterity, adaptability, and problem-solving capabilities of robotic systems.

- Development of more dexterous and adaptable robotic arms: Ongoing research and development focus on creating more sophisticated robotic arms capable of handling delicate materials and performing more complex tasks.

- Improvements in sensor technology and vision systems: Advanced sensor technology and vision systems can improve the robots' ability to perceive and respond to their environment, enhancing their accuracy and adaptability.

- Potential for collaborative robots (cobots) to work alongside humans: Cobots, designed to work alongside human workers, offer a promising approach to combining the strengths of both humans and robots in sneaker manufacturing.

Conclusion

The Robotic Limitations in Nike Sneaker Manufacturing are significant, highlighting the intricate nature of the production process and the limitations of current robotic technology in replicating human dexterity and adaptability. While automation offers potential benefits in efficiency and consistency, human labor remains crucial for quality control, troubleshooting, and handling unexpected situations. The future of sneaker manufacturing likely lies in a collaborative approach, combining the strengths of both human workers and advanced robotic systems. To stay abreast of developments in this evolving field, continue researching advancements in robotics and automation within the manufacturing industry, particularly focusing on solutions addressing the robotic limitations in Nike sneaker manufacturing and similar challenges. Further innovation is needed to create truly adaptable and cost-effective robotic systems capable of meeting the demands of this dynamic industry.

Featured Posts

-

Why Nike Shoe Manufacturing Remains A Challenge For Robots

Apr 22, 2025

Why Nike Shoe Manufacturing Remains A Challenge For Robots

Apr 22, 2025 -

The Complexities Of Robotic Nike Sneaker Production

Apr 22, 2025

The Complexities Of Robotic Nike Sneaker Production

Apr 22, 2025 -

English Language Leaders Debate 5 Crucial Economic Insights

Apr 22, 2025

English Language Leaders Debate 5 Crucial Economic Insights

Apr 22, 2025 -

Boosting Security Cooperation China And Indonesia

Apr 22, 2025

Boosting Security Cooperation China And Indonesia

Apr 22, 2025 -

Access To Birth Control The Impact Of Over The Counter Options Post Roe

Apr 22, 2025

Access To Birth Control The Impact Of Over The Counter Options Post Roe

Apr 22, 2025

Latest Posts

-

Belal Muhammad Vs Jack Della Maddalena At Ufc 315 Montreal Complete Event Details

May 12, 2025

Belal Muhammad Vs Jack Della Maddalena At Ufc 315 Montreal Complete Event Details

May 12, 2025 -

Mauricio Ruffy Perfects Spinning Kick Ahead Of Ufc 313

May 12, 2025

Mauricio Ruffy Perfects Spinning Kick Ahead Of Ufc 313

May 12, 2025 -

3 Must See Mma Fights 5 10 And 25 Minute Thrillers Mma Torch

May 12, 2025

3 Must See Mma Fights 5 10 And 25 Minute Thrillers Mma Torch

May 12, 2025 -

Ufc 315 Muhammad Vs Della Maddalena Full Fight Card Date And Viewing Guide

May 12, 2025

Ufc 315 Muhammad Vs Della Maddalena Full Fight Card Date And Viewing Guide

May 12, 2025 -

Conor Mc Gregor Supports Bkfc Fighters Aldo Inspired Press Conference Stunt

May 12, 2025

Conor Mc Gregor Supports Bkfc Fighters Aldo Inspired Press Conference Stunt

May 12, 2025